At LeuLeu LLC, we understand the importance of optimizing your supply chain operations to drive efficiency and enhance customer satisfaction. One of the key strategies that can significantly improve your logistics and distribution processes is cross-docking. In this comprehensive guide, we will explore the concept of direct transfer, its benefits, and how you can implement it successfully within your organization.

What is Cross-Docking?

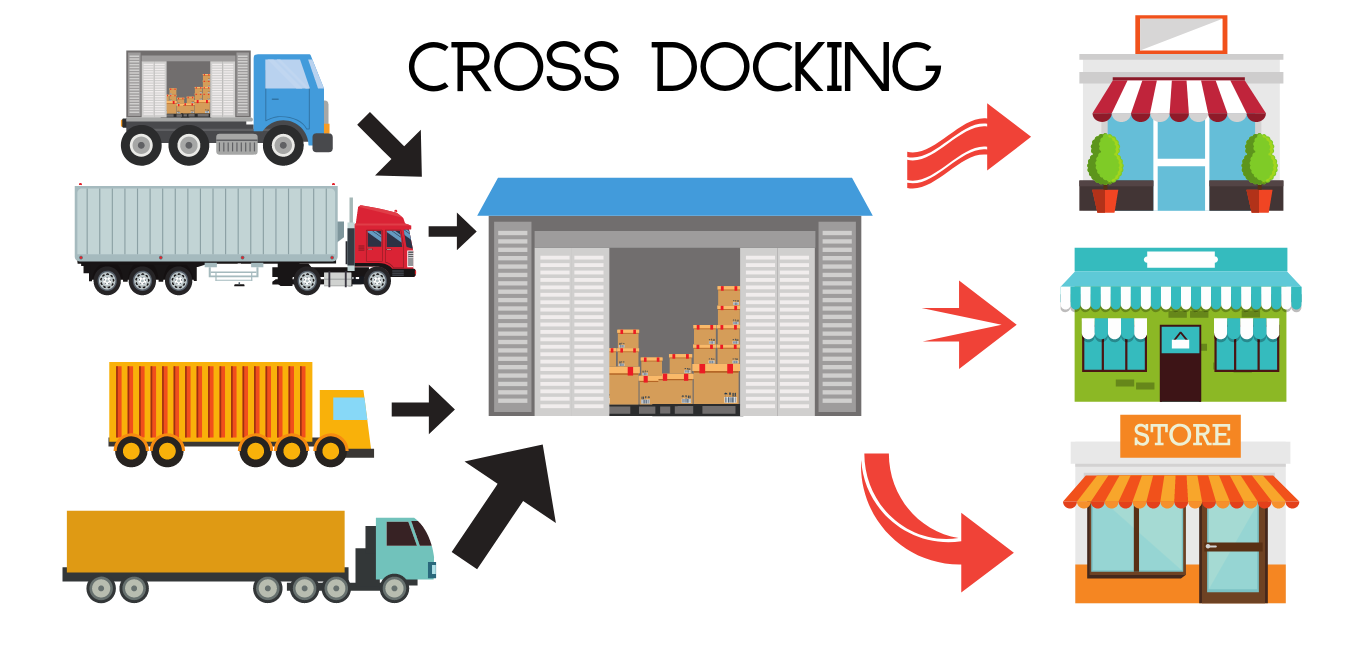

Cross-docking is a logistics technique that involves the direct transfer of products from inbound shipments to outbound shipments, with minimal or no storage in between. It enables a streamlined flow of goods, reducing handling and storage costs while expediting the delivery process. By bypassing traditional warehousing procedures, transshipment can help businesses achieve faster order fulfillment, improved inventory management, and enhanced operational efficiency.

The Benefits of Cross-Docking

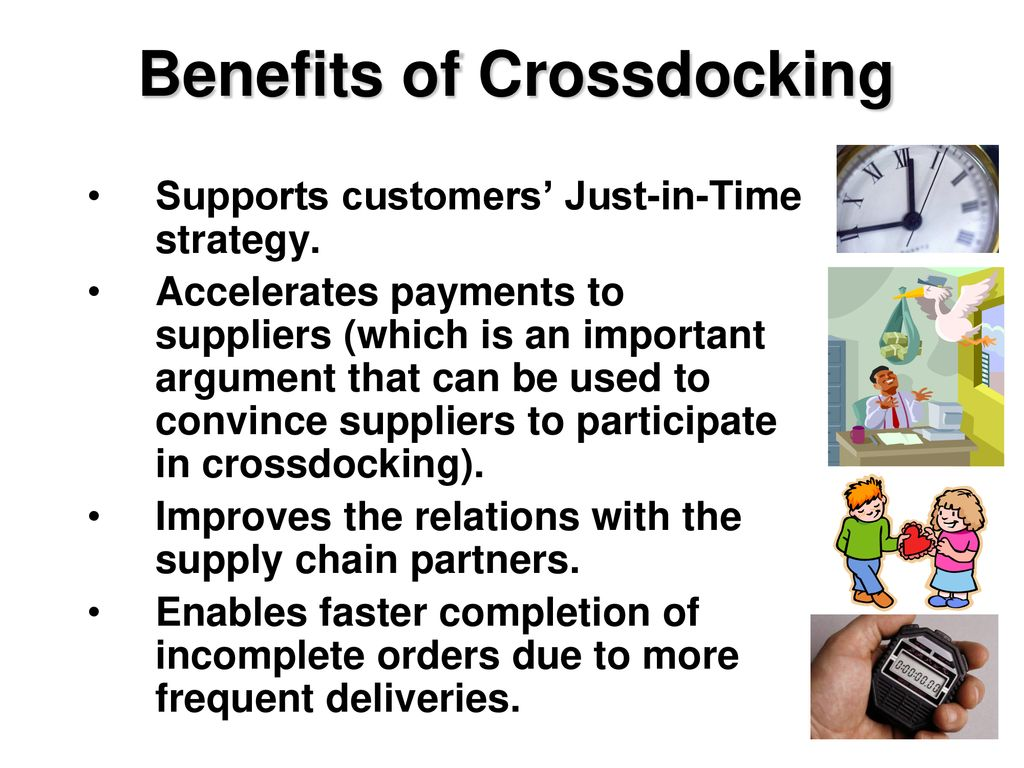

Implementing cross-docking into your supply chain strategy can bring a multitude of advantages to your business:

1. Reduced Inventory Holding Costs

With cross-docking, there is no need to store products for an extended period. By eliminating or minimizing inventory holding times, you can significantly reduce carrying costs, including warehousing expenses, insurance, and depreciation.

2. Improved Order Fulfillment Speed

By eliminating unnecessary storage and handling steps, cross-docking allows for faster order processing and shipment preparation. This speedier fulfillment process leads to shorter lead times, enabling you to meet customer demands more efficiently.

3. Enhanced Supply Chain Flexibility

Cross-docking offers increased flexibility in responding to fluctuations in demand and adapting to market changes. It allows for easier handling of rush orders, seasonal spikes, and product launches, ensuring timely delivery to customers without disruptions.

4. Cost Savings on Transportation

Since cross-docking minimizes the need for long-term storage and additional transportation between warehouses, it can result in significant cost savings on shipping and handling expenses. Consolidating shipments and reducing unnecessary travel distance can lead to lower fuel consumption and reduced carbon emissions.

5. Improved Inventory Control

Cross-docking enables real-time inventory visibility and control. By streamlining the flow of goods, you gain better insights into stock levels, allowing for more accurate demand forecasting, reducing stockouts, and optimizing inventory replenishment.

Implementing Cross-Docking: Best Practices

To successfully implement cross-docking within your supply chain, follow these best practices:

1. Strategic Supplier Collaboration

Establish strong partnerships with reliable suppliers who can deliver products promptly and consistently. Effective communication and coordination with suppliers are crucial to ensure that inbound shipments align with your cross-docking schedules.

2. Streamlined Inbound and Outbound Processes

Optimize your inbound and outbound processes to minimize delays and streamline the transfer of goods. Ensure that you have efficient loading and unloading systems, properly labeled packaging, and clearly defined protocols for handling different types of products.

3. Optimizing Warehouse Layout and Design for Cross-Docking Success

Design your warehouse layout to facilitate smooth transshipment operations. Implement a clear and logical flow of goods, with designated areas for sorting, staging, and loading. Use technologies like barcode scanning and RFID systems to enhance accuracy and traceability.

4. Advanced Technology Integration

Leverage advanced technology solutions to automate and optimize your direct transfer operations. Implement a robust warehouse management system (WMS) or transportation management system (TMS) to streamline processes, track shipments, and manage inventory effectively.

5. Performance Measurement and Continuous Improvement

Regularly monitor and measure key performance indicators (KPIs) related to direct transfer, such as order fulfillment speed, inventory turnover, and transportation costs. Analyze the data and identify areas for improvement to enhance operational efficiency and drive ongoing optimization.

Key Takeaways: Unlocking the Benefits of Cross-Docking

By embracing transshipment as a strategic component of your supply chain management, you can unlock numerous benefits, including reduced costs, faster order fulfillment, and improved inventory control. Remember to align your cross-docking implementation with your specific business needs and continually evaluate and refine your processes to stay ahead of the competition. At LeuLeu LLC, we are committed to helping you achieve supply chain excellence through effective cross-docking strategies. Contact us today to discuss how we can support your logistics optimization efforts.