In today’s increasingly interconnected and globalized world, businesses are constantly seeking efficient and cost-effective ways to manage their supply chains. One solution that has gained significant prominence in recent years is Third-Party Logistics, commonly known as 3PL. This comprehensive guide aims to provide you with everything you need to know about 3PL, including its definition, functions, benefits, and challenges.

What are third-party logistics (3PLS)?

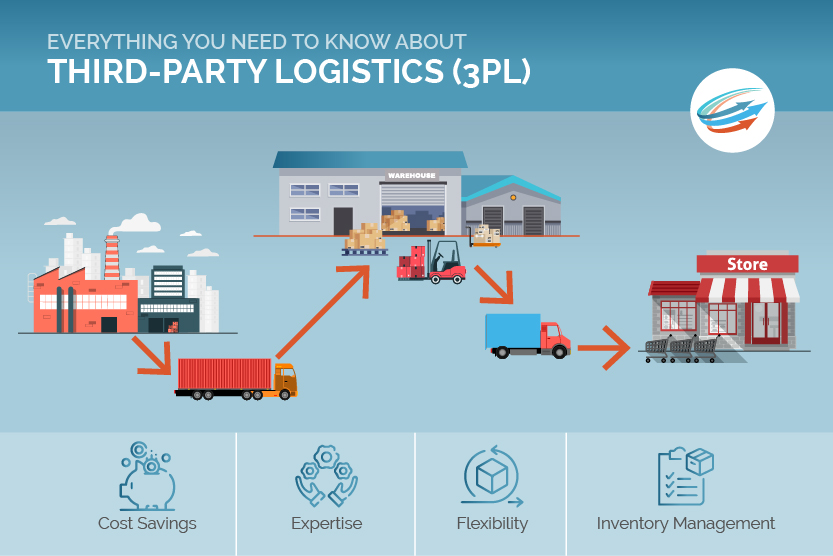

Third-party logistics (3PLs) refer to companies that provide outsourced logistics services to businesses. These companies specialize in handling various aspects of the supply chain, including transportation, warehousing, distribution, inventory management, and freight forwarding.

3PLs act as intermediaries between manufacturers or suppliers and their customers, streamlining and optimizing the logistics process. They offer expertise, infrastructure, and resources to manage and execute logistics operations efficiently. By outsourcing logistics functions to 3PLs, businesses can focus on their core competencies while leveraging the specialized knowledge and capabilities of these providers.

The services provided by 3PLs can vary depending on the specific needs of the client. Some common services offered by 3PLs include: Transportation, Warehousing and distribution, Inventory management, Order fulfillment, Customs brokerage, Value-added services.

3PLs can offer significant benefits to businesses, including cost savings, improved operational efficiency, access to a wider network of carriers and suppliers, scalability, and flexibility. They bring expertise, technology, and resources that enable businesses to optimize their supply chain and meet customer demands more effectively.

The 3PL order fulfillment process

The 3PL (Third-Party Logistics) order fulfillment process refers to the steps involved in outsourcing logistics and order fulfillment operations to a third-party logistics provider. These providers specialize in managing various aspects of the supply chain, including warehousing, inventory management, picking, packing, and shipping of orders on behalf of businesses. Here are the typical steps involved in the 3PL order fulfillment process:

Receiving and Inventory Management:

The 3PL provider receives incoming inventory from the client’s suppliers or manufacturing facilities.

They inspect the goods for any damage and verify the quantity and quality of the received items.

The inventory is then organized and stored in the 3PL provider’s warehouse.

Order Placement and Integration:

The client’s e-commerce platform or order management system sends order information to the 3PL provider.

The 3PL provider integrates their system with the client’s system to receive real-time order updates.

Order Processing:

The 3PL provider’s system retrieves the order details, including product SKUs, quantities, and shipping information.

Warehouse staff locates the ordered items in the inventory and prepares them for packing.

Order Picking and Packing:

Staff members pick the ordered items from their respective locations in the warehouse.

They verify the accuracy of the items and quantities picked against the order details.

The items are packed securely, ensuring appropriate packaging materials and labeling are used.

Shipping and Carrier Selection:

The 3PL provider selects the appropriate shipping carrier based on factors like delivery speed, cost, and destination.

They generate shipping labels and necessary documentation for the selected carrier.

The packages are handed over to the carrier for transportation to the customer’s address.

Tracking and Visibility:

The 3PL provider updates the order status and tracking information in their system.

They share tracking details with the client, enabling them and the customer to track the shipment’s progress.

Returns and Reverse Logistics (if applicable):

The 3PL provider handles customer returns and manages the reverse logistics process.

They inspect returned items, process refunds or exchanges, and update the inventory accordingly.

Throughout the entire order fulfillment process, the 3PL provider utilizes technology and systems to track inventory levels, monitor order status, and ensure efficient operations. By outsourcing these logistics functions to a specialized third-party provider, businesses can focus on their core competencies while leveraging the expertise and infrastructure of the 3PL provider to streamline their supply chain and enhance customer satisfaction.

What are the advantages and disadvantages of 3PL?

Advantages of 3PL

Third-party logistics (3PL) refers to the outsourcing of logistics and supply chain management functions to specialized companies. These companies take care of various aspects of the supply chain, such as transportation, warehousing, inventory management, and distribution. Here are some of the benefits of utilizing 3PL services:

Expertise and Resources

3PL providers are experts in logistics and supply chain management. They have the knowledge, experience, and resources to optimize operations, streamline processes, and find cost-effective solutions. By leveraging their expertise, businesses can benefit from efficient and well-managed logistics operations without having to build and maintain their own infrastructure.

Cost Savings

Partnering with a 3PL provider can lead to cost savings in several ways. First, businesses can avoid the significant upfront investment required to build and operate their own logistics infrastructure. They can also benefit from economies of scale achieved by 3PL providers through their extensive networks and large volumes of shipments. Additionally, 3PLs can negotiate better rates with carriers and suppliers due to their industry knowledge and relationships.

Scalability and Flexibility

3PL services offer scalability and flexibility to adapt to changing business needs. As businesses grow or experience seasonal fluctuations in demand, 3PL providers can quickly adjust their operations to accommodate these changes. They have the ability to scale up or down warehouse space, transportation capacity, and labor resources, allowing businesses to focus on their core competencies and respond to market dynamics efficiently.

Focus on Core Competencies

Outsourcing logistics to a 3PL allows businesses to concentrate on their core competencies and strategic initiatives. By offloading the time-consuming and complex logistics activities, organizations can allocate their resources and attention to areas such as product development, marketing, and customer service. This focus can lead to increased competitiveness and enhanced customer satisfaction.

Enhanced Technology and Systems

3PL providers invest in advanced technologies and systems to manage and optimize logistics operations. They often have robust warehouse management systems (WMS), transportation management systems (TMS), and other software solutions that provide real-time visibility, tracking, and reporting capabilities. Businesses can leverage these technologies without the need for substantial investments in their own infrastructure.

Improved Customer Service

Efficient logistics operations play a crucial role in delivering products to customers in a timely and reliable manner. By partnering with a 3PL provider, businesses can enhance their supply chain performance and meet customer expectations for timely deliveries, accurate order fulfillment, and effective reverse logistics. This can lead to improved customer satisfaction, repeat business, and positive brand reputation.

Global Reach

For businesses engaged in international trade or expanding into new markets, 3PL providers with global networks can offer valuable support. They have the knowledge and capabilities to navigate international regulations, customs procedures, and transportation requirements. Leveraging their established infrastructure and partnerships, businesses can access new markets with reduced complexity and risk.

It’s important to note that the specific benefits may vary depending on the nature of the business, industry, and the capabilities of the chosen 3PL provider.

Disadvantages of 3PL

Third-party logistics (3PL) involves outsourcing logistics and supply chain management activities to a specialized company. While 3PL offers various benefits, it also comes with its own set of challenges. Here are some common challenges faced in the realm of 3PL:

Dependency on a third party

When a company relies on a 3PL provider, it becomes dependent on their performance and efficiency. If the 3PL fails to meet expectations or encounters disruptions, it can affect the overall supply chain and customer satisfaction.

Communication and coordination

Effective communication and coordination between the company and the 3PL provider are vital. Challenges may arise due to differences in communication styles, time zones, language barriers, or misaligned goals. Lack of clear communication can lead to delays, errors, and misunderstandings.

Data integration and visibility

Seamless integration of data systems between the company and the 3PL is crucial for real-time visibility and information exchange. Challenges may arise when integrating disparate technologies, different data formats, or incompatible systems. Inadequate data visibility can hinder decision-making and responsiveness.

Quality control and service levels

Maintaining consistent quality standards and service levels across the supply chain is essential. However, the 3PL’s performance may not always align with the company’s expectations, leading to issues such as delays, errors, damaged goods, or subpar customer service. Ensuring proper quality control mechanisms and service level agreements is critical.

Overcoming these challenges requires proactive communication, strategic planning, mutual trust, and regular performance evaluations. Companies should carefully select reliable 3PL providers and establish clear expectations through well-defined contracts and service level agreements. Continuous monitoring, open dialogue, and collaborative problem-solving can help address challenges and build a successful 3PL partnership.

3PL vs. 4PL: What’s the difference?

3PL and 4PL are both terms used in the logistics and supply chain industry to describe different types of service providers. Let me explain the difference between them:

3PL (Third-Party Logistics)

3PL refers to a company that offers logistics and supply chain services to businesses. These services can include transportation, warehousing, inventory management, order fulfillment, and freight forwarding. 3PL providers act as intermediaries between the company and its customers, handling various aspects of the logistics process. They may also offer value-added services such as packaging, labeling, and customs clearance. The primary role of a 3PL provider is to streamline and optimize the supply chain operations of their clients.

4PL (Fourth-Party Logistics)

4PL is an extension of the concept of 3PL. A 4PL provider typically acts as a supply chain integrator, overseeing and managing the entire supply chain on behalf of the client. In addition to the services provided by 3PLs, 4PLs take a more strategic role and offer end-to-end supply chain management solutions. They coordinate and collaborate with various 3PLs and other service providers to design and implement supply chain strategies, optimize operations, and drive efficiency. 4PL providers often leverage advanced technologies and analytics to provide insights and improve decision-making across the supply chain.

In summary, while both 3PL and 4PL providers offer logistics and supply chain services, 3PLs primarily focus on specific operational aspects of the supply chain, while 4PLs take a more comprehensive approach, managing and integrating the entire supply chain for their clients. 4PL providers typically offer more strategic and consultative services, helping businesses achieve greater efficiency and competitiveness in their supply chain operations.

In conclusion, Third-Party Logistics (3PL) plays a vital role in today’s complex and globalized supply chain landscape. By outsourcing logistics functions to specialized service providers, businesses can focus on their core competencies while benefiting from streamlined operations, cost savings, and improved customer satisfaction.

Partnering with a reliable 3PL provider can bring numerous advantages, such as access to industry expertise, scalability, flexibility, and a global network of resources. These providers leverage advanced technologies, such as warehouse management systems and transportation management systems, to enhance efficiency and visibility throughout the supply chain.