Embarking on the journey of setting up a warehouse can be both exhilarating and challenging. Whether you’re a flourishing business looking to scale your distribution capabilities or a startup setting the groundwork for your supply chain, a well-planned warehouse setup acts as a powerful engine driving your operations forward.

Assessing Your Requirements and Creating a Warehouse Setup Plan

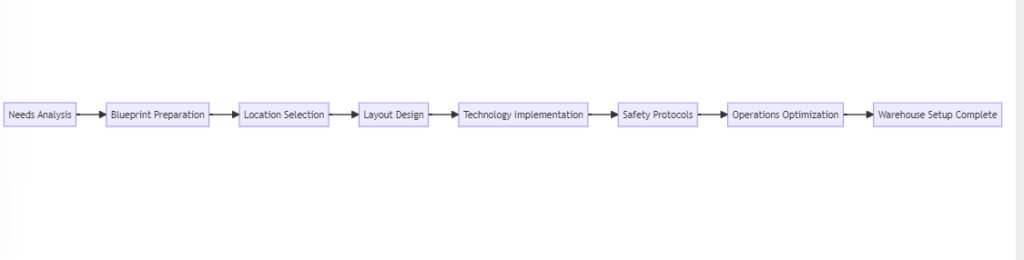

Before the physical setup of a warehouse, it’s essential to carry out a thorough needs analysis and prepare a comprehensive blueprint. Assess your business needs, estimate the inventory volume, and determine the necessary storage capacity. The blueprint should detail your warehouse’s layout, considering factors like product flow, employee safety, and space optimization.

Selecting the Right Warehouse Location

Choosing the right location can significantly impact your warehouse’s efficiency and profitability. Factors to consider include proximity to suppliers and customers, transportation access, and local labor costs. Ideally, your warehouse should be situated at a location that minimizes transportation costs and delivery times, while providing a sufficient pool of potential employees.

Optimizing Warehouse Setup for Enhanced Efficiency

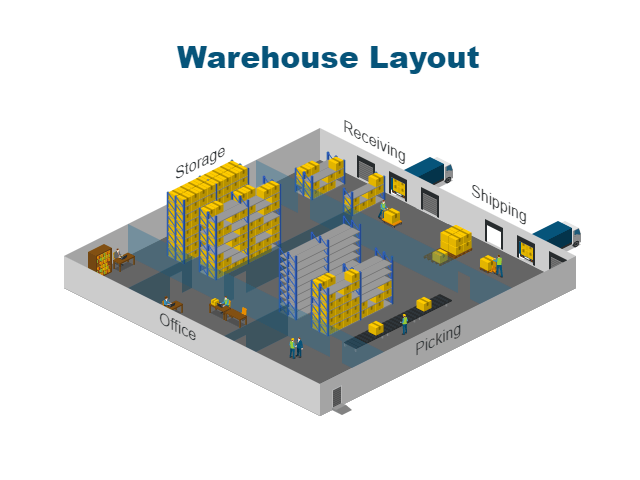

The layout of your warehouse should facilitate smooth product flow, from receiving to shipping. The design should also provide for easy access to inventory and efficient space utilization. The following are key elements to consider in warehouse layout design:

Dock Area – Warehouse Setup

A well-structured dock area is critical to efficient warehouse setup. This is where products first arrive and final shipments leave. Ensure that the dock is easily accessible, has sufficient space for loading and unloading, and is equipped with the necessary tools and equipment.

Storage Area – Warehouse Setup

The storage area should be designed for efficient retrieval and storage of items. Consider implementing a systematic approach such as ABC analysis for inventory categorization and layout arrangement. High-demand items (A-items) should be placed near the picking area for faster access.

Picking Area – Warehouse Setup

The picking area should be located in a central spot to reduce picking time. This is typically the busiest area in a warehouse, so it should be spacious enough to accommodate all picking activities without crowding.

Implementing Technology for Warehouse Management

In the era of digital transformation, implementing the right technology can significantly enhance warehouse operations. Warehouse Management Systems (WMS) automate processes, track inventory in real time, and generate valuable data for informed decision-making. Incorporating technologies like barcoding or RFID can further streamline inventory management.

Enhancing Warehouse Safety

Safety should never be compromised. Create a safety protocol and enforce it consistently. Regular safety training and proper signage can significantly reduce workplace accidents. Also, consider implementing ergonomics in your warehouse design to enhance worker comfort and reduce injuries.

Optimizing Warehouse Operations

Once the warehouse is set up, it’s critical to continuously review and optimize operations. Regular audits can help identify inefficiencies and potential improvements. Techniques such as Lean or Six Sigma can be beneficial in optimizing warehouse operations.

The above diagram represents the sequence of steps involved in warehouse setup. Each step feeds into the next, ultimately resulting in a fully functional, efficient, and safe warehouse.

Four Essential Processes to Consider in Warehouse Layout Design

Designing an efficient warehouse layout is a strategic process that requires considering several core operational processes. Let’s delve into the four vital ones that you should keep in mind to create an optimized and productive warehouse environment.

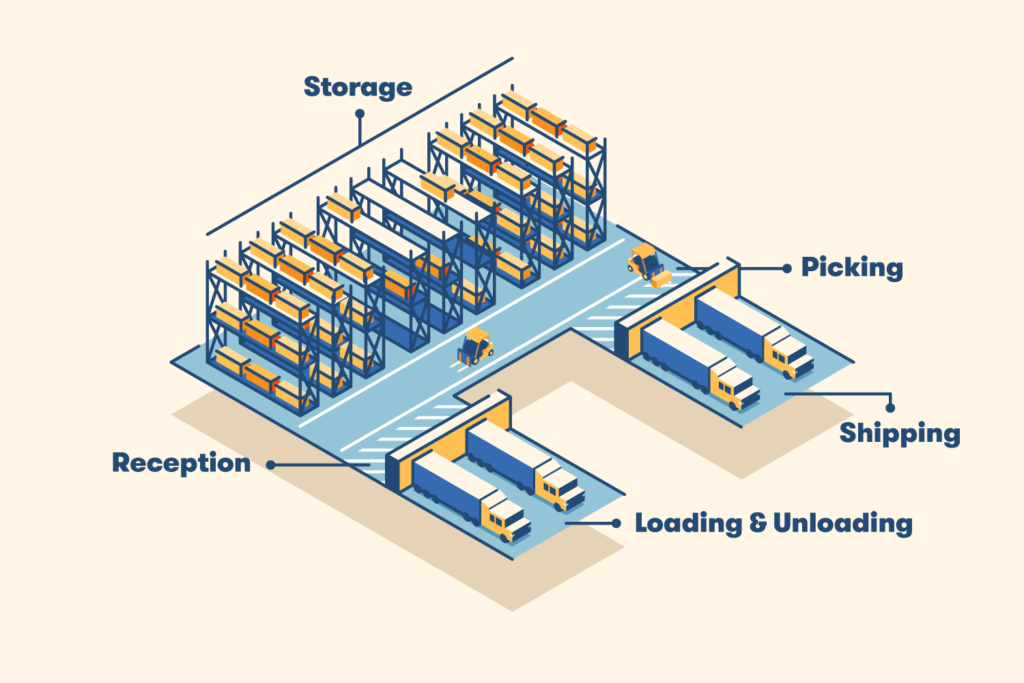

1. Receiving Process

The receiving area is the gateway to your warehouse. When designing this area, consider aspects such as space for inbound shipment inspection, immediate sorting, and temporary storage. Ensure that there’s sufficient space to accommodate peak volume times and prevent congestion that can slow down operations.

2. Storage Process

How you store items directly impacts space utilization and picking efficiency. Your storage design should take into account the diversity of your inventory—large, small, heavy, light, high-turnover, slow-moving—and allocate space accordingly. Consider implementing dynamic storage solutions such as adjustable racking systems to adapt to changing inventory needs.

3. Picking Process

An optimized picking process can significantly boost warehouse efficiency. Design your layout to minimize travel distance for pickers. For instance, use a strategic slotting plan to store high-frequency items closer to the dispatch area. Also, ensure that your layout facilitates different picking methods—like piece, case, or pallet picking—based on your operations.

4. Packing and Shipping Process

The packing and shipping area is the final touchpoint before your products head out the door. This area should be designed for efficiency and accuracy. There should be ample space for packing stations, equipment, and materials, and for checking orders. The shipping area should be close to the storage and picking areas to reduce product movement and facilitate quicker loading.

Conclusion

Setting up a warehouse is a complex, yet rewarding task. With careful planning, the right location, efficient design, technology implementation, safety protocols, and constant optimization, your warehouse can serve as the backbone of your business operations, driving success and growth.