Cost per unit is a fundamental concept in business and economics that plays a crucial role in determining the efficiency and profitability of a company’s operations. Whether you’re an entrepreneur, manager, or investor, understanding it is essential for making informed decisions and optimizing your business strategies.

In this comprehensive guide, we will delve into everything you need to know about cost per unit. We will start by defining what means and why it is a vital metric for businesses. We will explore different types of costs that contribute to the calculation of cost per unit, including fixed costs, variable costs, and total costs.

What is Cost Per Unit?

Cost Per Unit (CPU) refers to the average cost incurred to produce or acquire a single unit of a product or service. It is calculated by dividing the total cost by the number of units produced or acquired. is commonly used in manufacturing and retail industries to determine the profitability and efficiency of production or procurement processes.

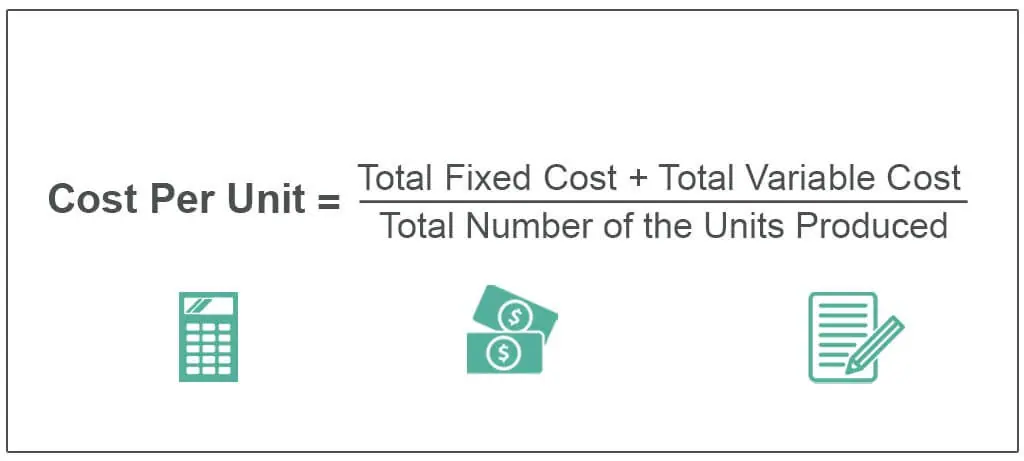

The formula to calculate cost per unit

The formula to calculate the cost per unit depends on the specific context and the components included in the cost calculation. However, in general terms, the formula for calculating is:

Cost per Unit = Total Cost / Number of Units

To use this formula, you need to determine the total cost incurred in producing a certain number of units and then divide that total cost by the number of units produced.

For example, let’s say you have a manufacturing company that incurred a total cost of $10,000 to produce 500 units. Using the formula, the cost per unit would be:

Cost per Unit = $10,000 / 500 = $20

Therefore, the result is $20.

The importance of cost per unit

Cost per unit deployment is a crucial metric that plays a significant role in various industries and businesses. It refers to the cost incurred for deploying or implementing a single unit of a product, service, or project. This metric is essential because it directly impacts a company’s profitability, competitiveness, and overall financial health. There are several reasons why cost per unit deployment holds great importance:

Cost Efficiency

Cost per unit deployment helps organizations determine the most cost-effective way to deploy their products or services. By calculating this metric, companies can identify areas of excessive spending and optimize their deployment strategies. It enables them to streamline operations, reduce waste, and allocate resources more efficiently.

Pricing Strategy

The cost per unit deployment plays a crucial role in determining the pricing strategy of a product or service. By accurately calculating the deployment costs, businesses can set competitive prices that cover their expenses and generate profits. Understanding the cost per unit deployment ensures that pricing decisions align with the organization’s financial goals and market conditions.

Profitability Analysis

Cost per unit deployment is an integral part of profitability analysis. By comparing with the revenue generated per unit, businesses can assess the profitability of their deployment activities. This analysis helps in identifying profitable product lines, services, or projects and allows for informed decision-making regarding resource allocation and investment.

Cost Control

Monitoring and managing the cost per unit deployment is essential for cost control. By tracking this metric regularly, organizations can identify cost overruns, inefficiencies, and areas of improvement. This information enables them to implement cost-saving measures, negotiate better deals with suppliers, and enhance their overall cost management strategies.

Competitive Advantage

In many industries, cost per unit deployment can be a significant determinant of competitive advantage. If a company can achieve lower deployment costs while maintaining the quality and efficiency of its products or services, it can offer competitive pricing to attract more customers. This advantage can lead to increased market share and sustained profitability in the long run.

How to reduce cost per unit?

Reducing can be achieved through various strategies aimed at optimizing processes, improving efficiency, and minimizing expenses. Here are some effective ways to reduce the this cost.

Streamline Operations

Analyze your production processes and identify areas where you can eliminate waste, reduce inefficiencies, and improve productivity. Look for bottlenecks, unnecessary steps, and non-value-added activities that can be eliminated or streamlined.

Supplier Optimization

Review your supply chain and assess your relationships with suppliers. Negotiate better terms, seek competitive bids, and explore alternative sourcing options. Consolidating suppliers and forming strategic partnerships can often lead to cost savings.

Economies of Scale

Increasing production volume can often result in economies of scale, reducing the average cost per unit. Identify ways to increase your production capacity and maximize output without sacrificing quality.

Lean Manufacturing

Implement lean manufacturing principles to eliminate waste, reduce inventory, and optimize production flow. This includes practices such as Just-in-Time (JIT) manufacturing, Kanban systems, and continuous improvement initiatives.

Automation and Technology

Evaluate opportunities for automation and technology adoption to streamline processes, improve accuracy, and reduce labor costs. Automated machinery, robotics, and advanced software systems can help optimize production and reduce human error.

Energy Efficiency

Identify energy-saving measures within your operations, such as using energy-efficient equipment, optimizing lighting, and implementing energy management systems. Lowering energy consumption can significantly reduce operating costs.

Material Cost Reduction

Evaluate your material costs and explore alternatives or negotiate better pricing with suppliers. Look for opportunities to reduce waste and scrap, optimize material usage, and improve inventory management.

Employee Training and Engagement

Invest in employee training and development programs to enhance skills, productivity, and job satisfaction. Engaged and well-trained employees are more likely to contribute to cost-saving initiatives and process improvements.

Continuous Improvement

Foster a culture of continuous improvement within your organization. Encourage employees to identify and suggest cost-saving ideas, and implement a structured process for evaluating and implementing these suggestions.

Benchmarking and Market Research

Regularly benchmark your costs against industry standards and competitors. Conduct market research to identify industry trends, new technologies, and innovative practices that can help reduce costs.

Remember, reducing the it requires a holistic approach and a focus on continuous improvement. It’s essential to regularly monitor and evaluate the effectiveness of your cost-saving initiatives and adjust strategies as needed.

It serves as a critical performance metric for businesses across industries, guiding their decision-making processes, pricing strategies, and profitability analysis. By understanding and managing the cost per unit deployment effectively, organizations can improve their cost efficiency, control expenses, and gain a competitive edge in the market. It is essential for companies to regularly evaluate and optimize their deployment processes to ensure that they are maximizing their resources, minimizing waste, and achieving sustainable growth.

Overall, it serves as a vital metric for evaluating financial performance, guiding pricing decisions, optimizing costs, and informing strategic choices. It provides a quantitative measure of the economic efficiency of production and helps businesses make informed decisions to improve profitability and sustainability.