Inventory Days on Hand is a crucial metric that measures the efficiency of inventory management within a business. It represents the average number of days a company holds its inventory before it is sold or consumed. By understanding this metric and its implications, businesses can make informed decisions to optimize their inventory levels and improve overall operational performance.

In this article, we will explore the meaning and significance of Inventory Days on Hand, delve into its calculation methods, and discuss strategies to reduce it effectively.

What is inventory days on hand?

Inventory Days on Hand, also known as Days Inventory Outstanding (DIO) or Days Sales of Inventory (DSI), is a financial metric that measures the average number of days it takes for a company to sell or consume its inventory. It represents the time it takes for inventory to be converted into sales or used in the production process.

provides valuable insights into how effectively a business manages its inventory levels. It helps assess the efficiency of inventory turnover and indicates how quickly a company can convert its inventory into revenue.

A high number of Inventory Days on Hand suggests that a business is holding onto its inventory for an extended period before it is sold or used. can tie up valuable resources and increase carrying costs. Conversely, a low number indicates that inventory is moving quickly, which can be a positive sign of efficient inventory management and strong sales.

How to calculate inventory days on hand

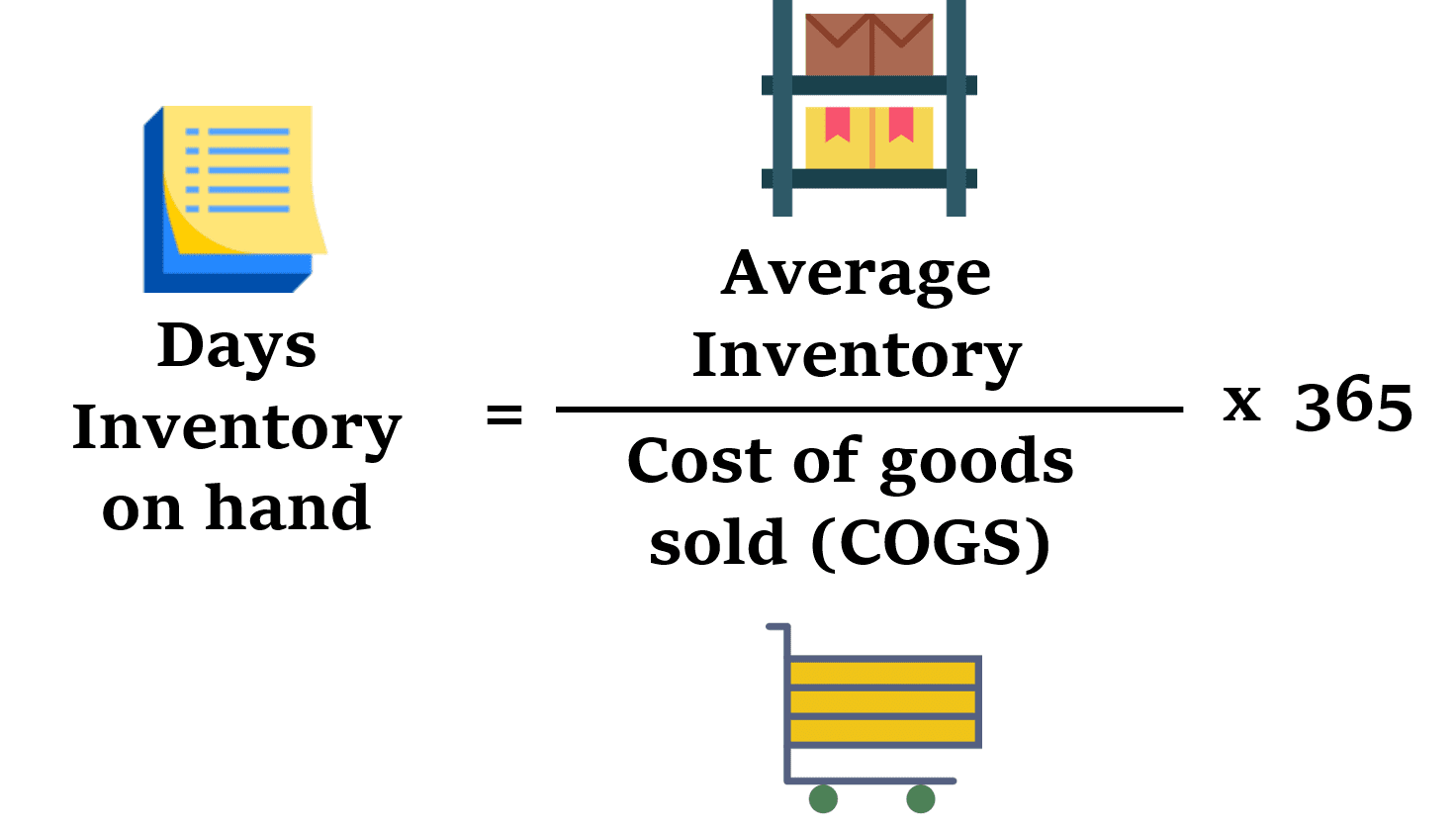

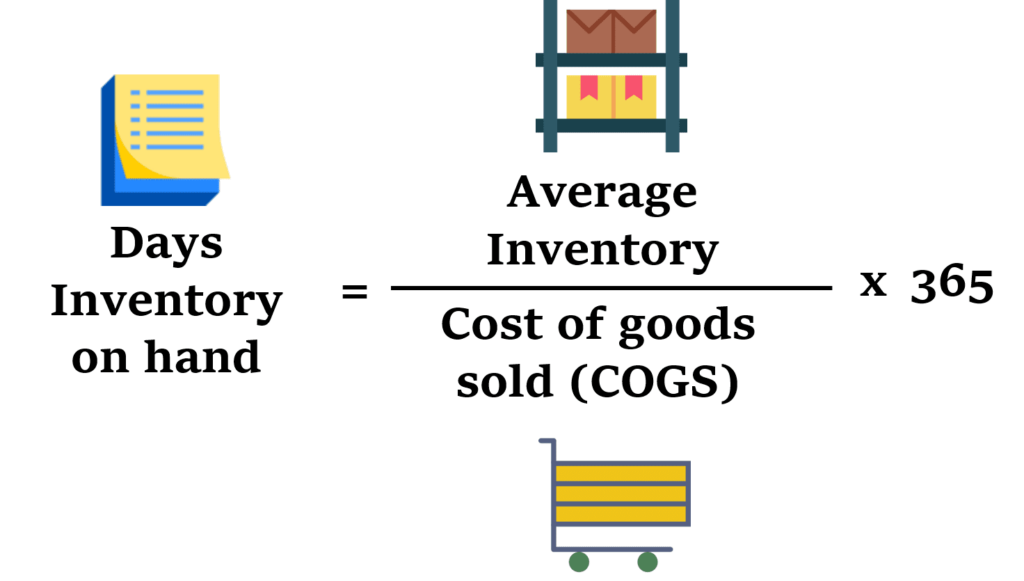

The formula of calculating it

To calculate the average inventory, you can use either the beginning inventory, ending inventory, or the average of the two. The Cost of Goods Sold (COGS) represents the direct costs associated with producing or acquiring the inventory items.

Here’s a step-by-step guide on calculating it:

Determine the time period for which you want to calculate the metric (e.g., a month, a quarter, a year).

Calculate the Average Inventory:

Determine the Cost of Goods Sold (COGS) for the same time period.

Determine the number of days in the time period. For example, if you are calculating it for a month, you would use 30 or 31, depending on the month.

Plug the values into the formula: Inventory Days on Hand = (Average Inventory / COGS) * Number of Days in a Period

By following these steps and plugging in the appropriate values, you can calculate the Inventory Days on Hand for your business. This metric provides valuable insights into your inventory management efficiency and can help you make informed decisions to optimize your inventory levels.

The importance of inventory days on hand

Inventory Days on Hand is an important metric that holds several key implications for businesses.

Here are some of the reasons why Inventory Days on Hand is significant:

Efficient Inventory Management

helps assess the effectiveness of inventory management practices within a business. By monitoring this metric, companies can identify potential issues such as excessive inventory or stockouts, enabling them to optimize their inventory levels and maintain a balanced supply.

Cash Flow Management

Inventory ties up a significant amount of capital, and a high Inventory Days on Hand indicates that a substantial portion of that capital is tied up in inventory for an extended period. By reducing Inventory Days on Hand, businesses can free up cash flow and allocate resources to other critical areas such as research and development, marketing, or debt reduction.

Cost Reduction

Carrying inventory incurs costs such as storage, insurance, and obsolescence. A higher number of Inventory Days on Hand indicates that inventory is being held for a longer duration. leading to increased carrying costs. By reducing Inventory Days on Hand, businesses can lower these costs and improve their profitability.

Supply Chain Efficiency

Inventory Days on Hand is closely linked to the efficiency of a company’s supply chain. A low number of Inventory Days on Hand implies a streamlined supply chain, with products moving quickly from suppliers to customers. This can result in improved customer satisfaction, reduced lead times, and increased responsiveness to market demands.

Forecasting and Planning

It can provide valuable insights for forecasting and planning purposes. By understanding the rate at which inventory is being consumed or sold, businesses can better anticipate demand, plan production schedules, and avoid overstocking or stockouts.

Performance Benchmarking

Business can use Inventory Days on Hand as a benchmarking tool to compare the efficiency of inventory management practices between different businesses or industry standards. It allows companies to gauge their performance relative to their competitors and identify areas for improvement.

In summary, plays a crucial role in optimizing inventory levels, managing cash flow, reducing costs, improving supply chain efficiency, and facilitating effective planning and benchmarking. By closely monitoring and actively managing this metric, businesses can enhance their operational performance and achieve better overall business outcomes.

How to reduce inventory days on hand

Reducing requires implementing effective inventory management strategies. Here are several approaches that can help in reducing it :

Demand Forecasting and Planning

Accurate demand forecasting allows businesses to better anticipate customer needs and adjust their inventory levels accordingly. By analyzing historical data, market trends, and customer insights, businesses can optimize their inventory levels and reduce the risk of overstocking or stockouts.

Efficient Reorder Point and Order Quantity

Setting appropriate reorder points and order quantities is crucial to avoid unnecessary stockouts or excess inventory. By utilizing tools like economic order quantity (EOQ) and just-in-time (JIT) inventory systems, businesses can minimize the time between inventory replenishment and customer demand, reducing it.

Vendor Management and Lead Time Reduction

Developing strong relationships with suppliers and optimizing lead times can significantly impact inventory days on hand. By working closely with suppliers to improve order processing, transportation, and delivery times, businesses can reduce the time it takes for inventory to reach their warehouses or production facilities.

Inventory Segmentation and Classification

Analyzing inventory data and segmenting products based on their demand patterns, profitability, and criticality can help prioritize inventory management efforts. By focusing on high-demand or high-value items, businesses can allocate resources more effectively, reducing inventory days on hand for these specific products.

Continuous Improvement and Performance Measurement

Regularly reviewing and analyzing inventory management performance metrics, such as Inventory Days on Hand, can help identify areas for improvement. Continuous improvement initiatives, such as process optimization, supplier evaluation, and demand planning refinement, can lead to further reductions in inventory days on hand over time.

Remember that the most effective approach to reducing inventory days on hand will vary depending on the specific industry, business model, and operational requirements.

It is essential for businesses to continuously monitor and analyze their inventory management practices and make adjustments as needed.