Retail logistics plays a vital role in the success of the retail industry by ensuring the efficient movement of products from suppliers to consumers. With the ever-increasing complexity of supply chains and the growing expectations of customers, it has become essential for retailers to understand the different types and functions of retail logistics. By doing so, they can identify areas for improvement and implement strategies to enhance their logistical operations.

By delving into the world of retail logistics and understanding its types, functions, and methods for improvement, retailers can gain a competitive edge in the dynamic retail industry. This article aims to provide valuable insights and practical advice to help retailers optimize their logistics operations and achieve long-term success in meeting customer demands.

Overview about retail logistics

What is retail logistics?

Retail logistics refers to the process of planning, implementing, and controlling the efficient flow of products and information within the retail supply chain. It involves managing the movement of goods from the manufacturer or supplier to the retailer and ultimately to the end consumer. The goal of retail logistics is to ensure that the right products are available at the right place, at the right time, and in the right condition.

Key components of include: Inventory management, Warehousing and distribution, Order processing, Transportation, Reverse logistics, Technology and information systems.

Effective retail logistics can result in various benefits for retailers, including improved customer satisfaction, reduced costs, enhanced inventory control, faster order processing, and optimized supply chain operations. It plays a crucial role in ensuring the smooth flow of products from suppliers to consumers in the retail industry.

Types Of Retail Logistics:

Inbound Logistics

Inbound logistics involves the movement and management of raw materials, components, and goods from suppliers or manufacturers to the retail distribution centers or warehouses. It includes activities such as transportation, receiving, inspection, and inventory management of incoming products.

Outbound Logistics

Outbound logistics focuses on the distribution of finished goods from the retail distribution centers or warehouses to the individual retail stores or directly to customers. This includes activities like order processing, picking, packing, and transportation to ensure timely delivery of products.

Warehouse Management

Warehouse management is an integral part of retail logistics. It involves efficiently organizing and managing the storage, handling, and movement of products within the warehouses or distribution centers. This includes activities such as inventory control, order fulfillment, space optimization, and ensuring accurate stock levels.

Inventory Management

Inventory management is crucial in retail logistics to ensure optimal stock levels and availability of products. It involves tracking, monitoring, and controlling the inventory across the supply chain, including warehouses, distribution centers, and retail stores. Effective inventory management helps avoid stockouts, minimize excess inventory, and streamline order fulfillment.

E-commerce Logistics

With the growth of online retail, e-commerce logistics has become increasingly important. It includes managing the fulfillment of online orders, including order processing, picking, packing, and last-mile delivery to customers’ doorsteps. E-commerce logistics often involves specialized strategies to handle high order volumes, multiple delivery options, and customer expectations for fast and reliable shipping.

These types of retail logistics are interconnected and collectively contribute to the smooth flow of products within the retail supply chain. Effective coordination and integration of these logistics types are crucial for retailers to meet customer demands, optimize operations, and gain a competitive advantage in the retail industry.

The main factors which impact on retail logistics

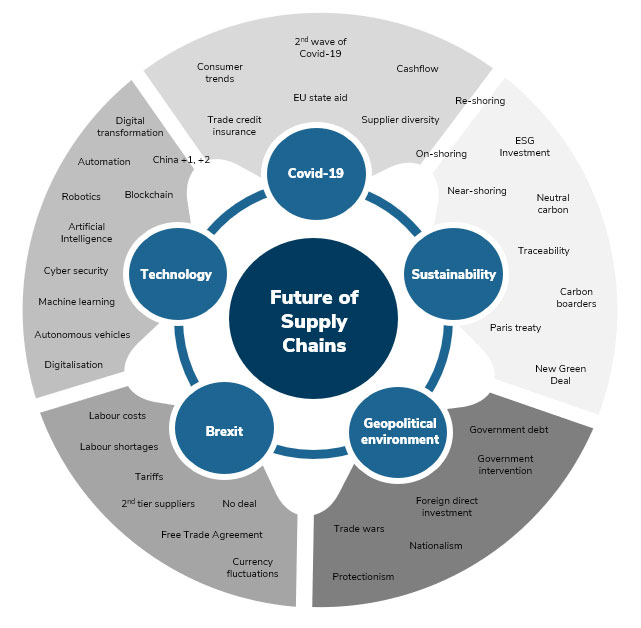

Several factors can significantly impact retail logistics. These factors can vary based on the specific industry, market dynamics, and the nature of the retail operations. However, some of the main factors that commonly influence retail logistics include:

Customer Demand and Expectations

Customer preferences, behaviors, and expectations have a direct impact on retail logistics. Fluctuations in demand, seasonal variations, and the need for faster order fulfillment can require retailers to adjust their logistics strategies to ensure timely delivery and meet customer expectations.

Supply Chain Complexity

The complexity of the retail supply chain, including the number of suppliers, distribution centers, and retail outlets, can greatly impact logistics operations. A complex supply chain often requires more intricate coordination, efficient inventory management, and optimized transportation routes to ensure smooth product flow.

Inventory Management

Effective inventory management is crucial in retail logistics. Maintaining optimal inventory levels, minimizing stockouts, managing perishable goods, and handling seasonal inventory fluctuations are essential to ensure availability while reducing holding costs and minimizing the risk of excess inventory.

Transportation Infrastructure

The state of transportation infrastructure, including roads, railways, ports, and airports, can significantly impact retail logistics. Efficient transportation systems and networks enable faster and more cost-effective movement of goods, while bottlenecks or disruptions in transportation infrastructure can lead to delays and increased logistics costs.

Technology and Data Management

Technology plays a crucial role in modern retail logistics. Advanced systems for inventory tracking, order processing, warehouse management, and transportation optimization enable real-time visibility and data-driven decision-making. Implementing and effectively utilizing such technologies can greatly enhance logistics operations.

Competitive Landscape

The competitive environment in the retail industry influences logistics strategies. Retailers need to respond to competitors’ actions, such as offering faster delivery options or expanding their product range, which can impact logistics requirements and necessitate operational adjustments to maintain a competitive edge.

By considering and effectively managing these factors, retailers can optimize their retail logistics operations, improve efficiency, and meet customer expectations in today’s rapidly evolving retail landscape.

Importance Of Supply Chain In Retail Logistics:

The supply chain plays a pivotal role in retail logistics and is of utmost importance for the success of retail operations.

Why the supply chain is vital in retail logistics:

Seamless Product Flow

An efficient supply chain ensures the smooth flow of products from suppliers to retail stores and ultimately to customers. It involves the coordination of various activities such as procurement, production, transportation, and distribution to minimize disruptions, delays, and bottlenecks. A well-functioning supply chain enables retailers to consistently meet customer demands and enhance customer satisfaction.

Timely Delivery

A well-managed supply chain ensures the timely delivery of products to retail stores or customers’ doorsteps. It involves optimizing transportation routes, coordinating logistics activities, and minimizing lead times. Timely delivery is crucial for retailers to maintain adequate inventory levels, prevent stockouts, and meet customer expectations, especially in today’s fast-paced retail environment.

Inventory Optimization

An effective supply chain helps retailers optimize their inventory levels and minimize holding costs. By closely managing the flow of products, retailers can ensure optimal stock levels, reduce excess inventory, and avoid stockouts. This results in improved cash flow, reduced carrying costs, and increased operational efficiency.

Cost Efficiency

A well-designed and well-executed supply chain can lead to cost savings for retailers. By optimizing transportation routes, consolidating shipments, negotiating favorable contracts with suppliers and carriers, and streamlining logistics processes, retailers can reduce transportation costs, inventory holding costs, and overall operational expenses.

Customer Satisfaction

The supply chain has a direct impact on customer satisfaction. A well-functioning supply chain enables retailers to provide consistent product availability, on-time delivery, and accurate order fulfillment. By meeting or exceeding customer expectations, retailers can enhance customer loyalty, attract repeat business, and strengthen their brand reputation.

How to improve retail logistics

Improving retail logistics is essential for enhancing operational efficiency, reducing costs, and meeting customer expectations. Here are some strategies and approaches

Streamline Inventory Management

Implementing effective inventory management practices can optimize stock levels and reduce holding costs. Retailers should leverage inventory management systems to accurately track stock levels, forecast demand, and identify slow-moving or obsolete items. This helps in maintaining optimal inventory levels, reducing stockouts, and minimizing excess inventory.

Enhance Supply Chain Visibility

Improving visibility across the supply chain enables retailers to make better-informed decisions and proactively address potential disruptions. Implementing technologies like barcode scanning, RFID, or real-time tracking systems can provide real-time visibility into the movement of products, from suppliers to retail stores. This helps in identifying bottlenecks, streamlining processes, and improving overall supply chain efficiency.

Optimize Transportation Routes

Analyzing transportation routes and modes can lead to cost savings and faster delivery times. Retailers should explore options for route optimization, considering factors like distance, traffic patterns, and carrier capabilities. Consolidating shipments and leveraging efficient transportation modes can reduce transportation costs and enhance delivery speed.

Implement Warehouse Automation

Embracing automation technologies, such as robotics and warehouse management systems, can significantly improve warehouse efficiency. Automated systems can streamline order picking, packing, and inventory management processes, reducing errors and increasing throughput. Retailers should assess their warehouse operations and invest in automation where applicable.

Foster Collaboration with Suppliers

Developing strong partnerships and fostering collaboration with suppliers can lead to improved logistics outcomes. Retailers can work closely with suppliers to optimize order quantities, delivery schedules, and packaging specifications. This collaborative approach helps in reducing lead times, improving order accuracy, and enhancing overall supply chain performance.

In summary, the supply chain is of paramount importance in retail logistics. It facilitates the seamless flow of products, ensures timely delivery, optimizes inventory levels, reduces costs, enhances customer satisfaction, enables agility, and provides a competitive advantage. Retailers that prioritize and invest in their supply chain capabilities are better positioned to thrive in the competitive retail industry.

- Inventory Days on Hand: Meaning, Calculation and How to reduce ithttps://leuleullc.com/2023/07/03/inventory-days-on-hand-meaning-calculation-and-how-to-reduce-it/