Hello there! Ever pondered the journey of your online orders before they land at your doorstep? Welcome to ‘Goods in Transit,’ a key stage in the supply chain that significantly shapes business operations. Join us as we unpack its intricacies, examine the role of technology, and guide you through this fascinating process. Ready to embark on this enlightening journey? Let’s dive in!

Understanding the Concept of Goods in Transit

Goods in transit define the inventory items that have been shipped by a seller, but not yet received by the buyer. Being an integral part of the supply chain process, the effective handling of shipment in transit significantly impacts both inventory control and financial accounting.

What are Goods in Transit?

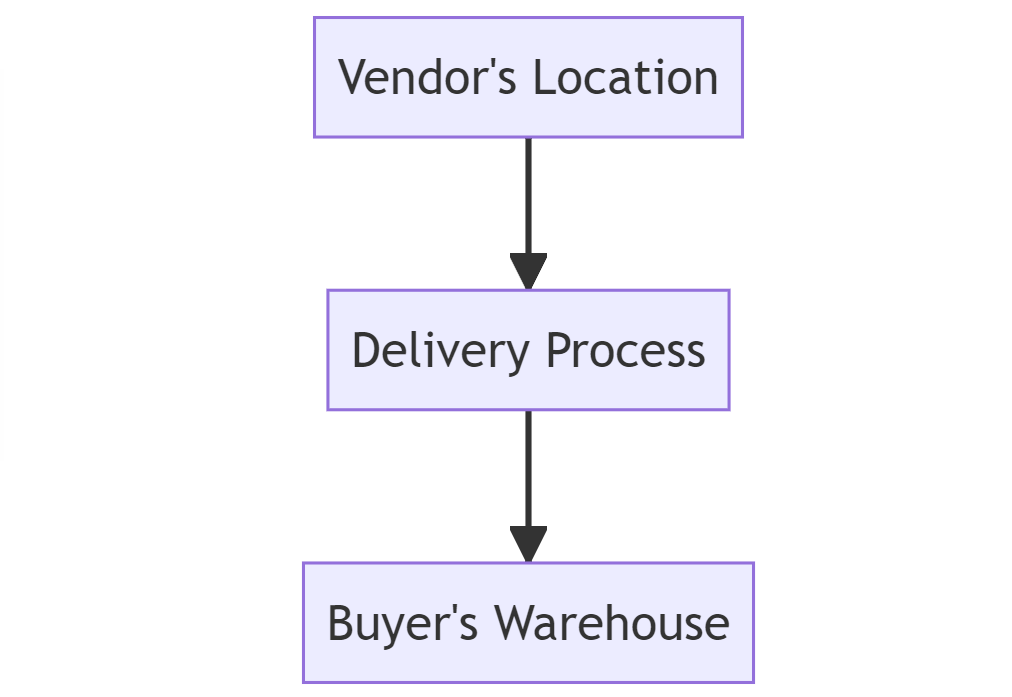

Simply put, inventory in transit are the products that are neither at the vendor’s location nor the buyer’s warehouse. Instead, they’re in the delivery process, traveling from one point to another.

Accounting for Goods in Transit

In accounting, shipment in transit are considered an asset and are included in a company’s inventory totals. Therefore, understanding who bears the risk during transit — the seller or the buyer — is essential for accurate record-keeping.

FOB Shipping Point

Under the Free-On-Board (FOB) shipping point terms, ownership transfers from the seller to the buyer as soon as the goods leave the seller’s premises. From this moment, the shipment in transit are officially part of the buyer’s inventory, even though they haven’t physically received them yet.

FOB Destination

In contrast, under FOB destination terms, ownership doesn’t transfer until the buyer receives the goods. Hence, while in transit, the goods are still part of the seller’s inventory.

The Impact of Goods in Transit on Inventory Management

Proper management of inventory in transit is critical for maintaining optimal inventory levels. It helps prevent stockouts, overstocking, and ensures smoother operations.

Avoiding Stockouts

By tracking inventory in transit, businesses can estimate when they’ll receive the inventory and plan their operations accordingly, mitigating the risk of stockouts.

Preventing Overstocking

Similarly, awareness of incoming inventory helps prevent overstocking, which can lead to wasted resources and unnecessary storage costs.

Tracking Goods in Transit: What Technology to Use

Technology plays a pivotal role in effectively tracking inventory in transit. By leveraging cutting-edge tools, businesses can get real-time updates, which helps streamline operations and improve decision-making.

Real-time GPS Tracking

Global Positioning System (GPS) tracking provides real-time updates about the location of shipment in transit. This helps businesses predict delivery times more accurately.

RFID Tags

Radio Frequency Identification (RFID) tags are another efficient tool to track goods. They provide granular data about each item in transit, enhancing visibility and control.

Final Thoughts: The Future of Goods in Transit

The future of shipment in transit looks promising, with technological advancements poised to revolutionize how we track and manage inventory. By embracing these technologies, businesses can better manage their goods in transit and stay ahead in the competitive world of commerce.

Remember, the key to effective inventory management is keeping a keen eye on your shipment in transit. It could be the difference between a smoothly running operation and one fraught with unnecessary complications. Start investing in tracking technologies today for a better tomorrow.