Today, we offer an in-depth analysis of lead time, the implications they have on businesses, and how understanding and reducing these timelines can augment your supply chain. We’ll also provide actionable strategies to streamline operations and ensure customer satisfaction.

Understanding Lead Time in Supply Chain Management

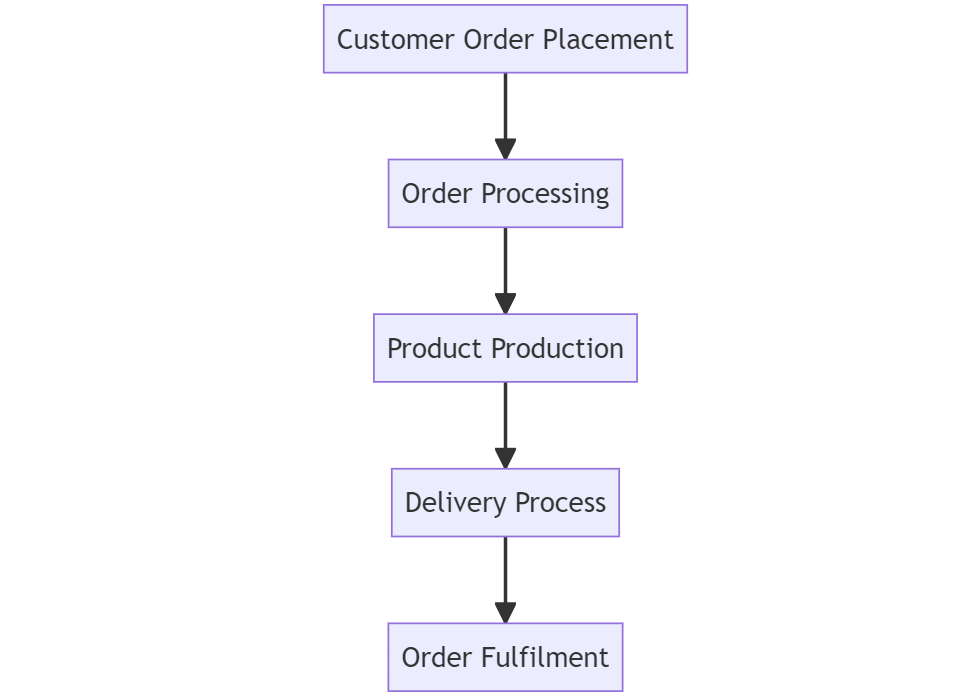

Lead time is the sum total of time it takes from the moment a customer places an order until the product is in their hands. In simple terms, it’s the duration between order initiation and order fulfillment.

The Importance of Reducing Lead Time

Reducing lead times benefits businesses in many ways, from enhancing customer satisfaction to mitigating inventory risks. The shorter your lead times, the faster you can meet customer demand, creating a positive business reputation.

How to Reduce Lead Time: Implementing Effective Strategies

Streamlining the Order Processing System

One effective way to reduce throughput time is by improving the efficiency of the order processing system. Employing automation and real-time data can drastically decrease processing times, enhance accuracy, and minimize the potential for errors.

Optimizing Inventory Management

An efficient inventory management system can help reduce lead time by ensuring the right amount of stock is available when needed. Implementing demand forecasting and just-in-time (JIT) inventory practices can significantly minimize throughput time.

Enhancing Supplier Relationships

Establishing strong supplier relationships is crucial. Prompt and clear communication, along with developing mutually beneficial agreements, can lead to faster response times and reduced lead times.

Improving Production Processes

Optimizing production processes by employing lean manufacturing principles can result in quicker, more efficient production cycles. This strategy not only decreases lead time but also minimizes waste and increases productivity.

Overcoming Challenges in Reducing Lead Time

Reducing throughput time can present its own set of challenges, including predicting customer demand, managing supplier risks, and improving operational efficiency. Businesses must strive to maintain a delicate balance between reducing lead times and ensuring operational stability.

Developing Accurate Demand Forecasts

To overcome these challenges, businesses can implement accurate demand forecasting methods. Machine learning and AI-driven models can help businesses predict customer demand more accurately, facilitating more efficient planning and reducing lead times.

Managing Supplier Risks

To manage supplier risks, businesses should diversify their supplier base, minimizing the impact of potential disruptions in the supply chain and, in turn, reducing lead times.

Boosting Operational Efficiency

By adopting lean principles, businesses can eliminate waste in their processes, increase efficiency, and subsequently reduce lead times.

Conclusion

In essence, understanding and reducing lead time is critical to improving business efficiency and customer satisfaction. By implementing the strategies outlined above, businesses can create a robust and responsive supply chain that is well-equipped to meet customer demand in a timely manner.

Remember, the key to successfully reducing lead times lies in continuous monitoring and improvement. It’s not a one-time effort but an ongoing process that requires diligence and commitment to excellence. Your customers, your bottom line, and your overall business reputation will thank you for it.