If there’s one thing that can make or break a business, it’s efficient supply inventory management. Without a well-organized inventory, you’re navigating in the dark, risking product shortages and overstocks, both of which can be detrimental to your bottom line. So let’s delve into the intricacies of supply inventory management and understand how you can optimize it to maximize efficiency and profitability.

Understanding the Importance of Supply Inventory Management

A well-managed inventory not only ensures smooth operations but also forms the backbone of an efficient supply chain. It aids in maintaining an optimal stock level, reduces the risk of inventory obsolescence, and ultimately contributes to customer satisfaction.

Decoding Successful Supply Inventory Management

To manage supply inventory effectively, we must comprehend its multiple facets. These include understanding different types of inventory, mastering various inventory management techniques, and leveraging modern tools and technologies.

Types of Inventory: Raw, WIP, and Finished Goods

Inventory is categorized into three primary types: raw materials, work-in-progress (WIP), and finished goods. Raw materials are the basic ingredients for production, WIP inventory is in the production process, and finished goods are ready for sale. Understanding these categories can help manage inventory at each stage and ensure a seamless production process.

Inventory Management Techniques: FIFO, JIT, and Safety Stock

There are several techniques to manage inventory effectively. Some of the most commonly used methods include First-In-First-Out (FIFO), Just-In-Time (JIT), and maintaining Safety Stock.

FIFO ensures that the oldest inventory items are used first, reducing the risk of spoilage. JIT, on the other hand, optimizes inventory management by receiving goods only as they are needed, reducing inventory holding costs. Safety Stock acts as a buffer to prevent stockouts during unexpected demand fluctuations.

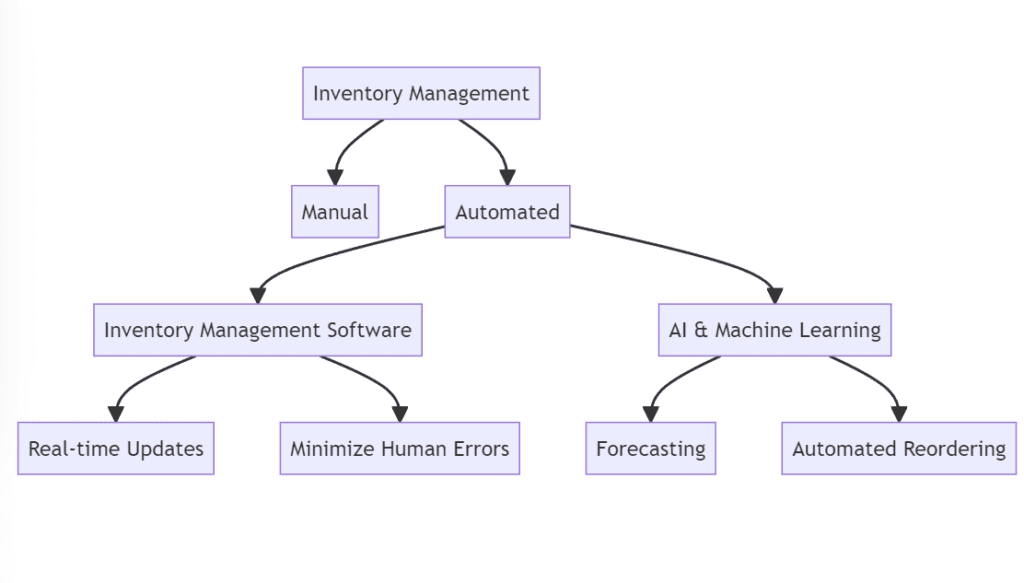

Leveraging Modern Tools and Technology

The digital revolution has transformed inventory management. Today, we have a plethora of inventory management software at our disposal, automating many manual tasks and providing real-time inventory updates. These tools help minimize human error, provide insights for better decision-making, and enable more efficient inventory management.

Creating an Effective Supply Inventory Management System

Building an effective supply inventory management system involves a series of steps. From forecasting demand to routinely auditing your inventory, every step contributes to more efficient inventory management.

Forecasting Demand: The Starting Point

Effective inventory management begins with accurate demand forecasting. By analyzing past sales data and market trends, we can predict future demand and ensure we have sufficient inventory to meet it.

Regular Audits: Keeping Check

Even with the best inventory management software, regular audits are necessary. They help verify the accuracy of the software and identify potential issues before they become significant problems.

Efficient Warehouse Management: The Backbone

An organized warehouse ensures easy access to items, reduces retrieval time, and ultimately enhances operational efficiency. Utilizing techniques such as ABC analysis can help prioritize inventory and streamline warehouse operations.

The Impact of Efficient Supply Inventory Management

Efficient supply inventory management goes beyond just maintaining optimal stock levels. It plays a crucial role in improving customer satisfaction, enhancing cash flow, and ultimately driving business growth.

Boosting Customer Satisfaction: Delivering Promises

With efficient inventory management, we can ensure we always have enough stock to fulfill orders. This leads to timely deliveries, fewer backorders, and ultimately, happier customers.

Enhancing Cash Flow: Optimal Stock Levels

Maintaining optimal inventory levels means you’re not tying up too much cash in stock. It reduces storage and holding costs, minimizes losses from obsolete stock, and improves cash flow.

Driving Business Growth: The Ultimate Goal

With improved cash flow and customer satisfaction, businesses are in a better position to invest in growth opportunities. Efficient inventory management essentially forms the foundation for sustainable business growth.

In Conclusion

A well-orchestrated supply inventory management strategy is no less than a superpower for businesses. By understanding its nuances and leveraging modern technology, we can transform our inventory management practices, enhancing efficiency and profitability.

Remember, effective inventory management is not a one-time effort, but a continuous process of monitoring, analyzing, and optimizing. So let’s embark on this journey of inventory excellence and steer our business towards sustainable growth.