Order fulfillment is a fundamental process within the realm of commerce that encompasses the journey from the moment a customer places an order to the successful delivery of the purchased goods or services. It involves a series of intricate steps, meticulously orchestrated to ensure timely, accurate, and satisfactory delivery to the end consumer. The significance of this process extends far beyond mere logistics; it plays a pivotal role in shaping customer satisfaction, brand reputation, and the competitive edge of businesses in today’s market.

What is order fulfillment?

Order fulfillment refers to the complete process a company undergoes from the moment a customer places an order to the point where the product or service is delivered to the customer. It involves various steps and tasks, including receiving, processing, and delivering orders to customers in a timely and efficient manner.

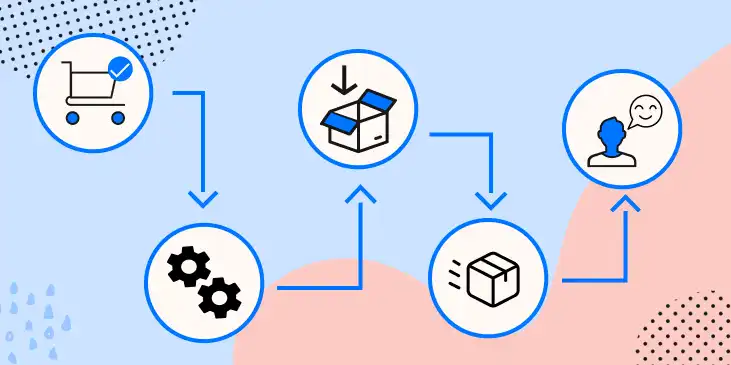

How does the order fulfillment process work?

The order fulfillment process typically involves several key steps:

Order Processing

This stage begins when a customer places an order. It involves validating the order, confirming payment, and checking the inventory to ensure the items are available for shipment.

Picking and Packing

Once the order is verified, the items are picked from the warehouse or inventory, often with the help of technology like barcode scanners or automated systems. After picking, the items are packed securely, often in appropriate packaging, and prepared for shipping.

Shipping

The packed order is sent to the shipping department, where shipping labels are generated and affixed. The shipping method is selected based on customer preference or company policies. The package is then sent to the shipping carrier for delivery.

Shipment Tracking

After the package leaves the warehouse, the customer is often provided with a tracking number. This allows them to monitor the status of their shipment and estimated delivery date.

Delivery and Customer Satisfaction

The final step is the delivery of the package to the customer. The goal is to ensure that the package arrives on time, in good condition, and meets the customer’s expectations. This final step is crucial for customer satisfaction and retention.

Efficiently managing each of these steps is essential for a successful order fulfillment process. Companies often use technology, such as inventory management software and automated systems, to streamline these steps and ensure accuracy and timeliness in fulfilling orders.

Why is order fulfillment important?

Here are some key reasons why order fulfillment is important:

Customer Satisfaction

Timely and accurate order fulfillment is crucial for ensuring customer satisfaction. Meeting delivery expectations and providing the right products in good condition enhances the customer experience, encouraging repeat purchases and positive word-of-mouth.

Brand Reputation

Efficient order fulfillment contributes to a positive brand image. Consistently meeting orders on time and accurately demonstrates reliability and professionalism, which can lead to increased brand loyalty and trust.

Competitive Edge

Businesses that excel in order fulfillment gain a competitive advantage. Fast and accurate delivery, along with excellent customer service, can set a company apart from competitors in the market.

Operational Efficiency

Streamlining order fulfillment processes can lead to improved operational efficiency. This includes optimized inventory management, reduced errors, and improved logistics, which can lower costs and increase productivity.

Customer Retention and Loyalty

A positive order fulfillment experience is more likely to encourage repeat business. When customers have a smooth and satisfying experience with a company’s order fulfillment, they’re more likely to return and remain loyal to the brand.

In summary, order fulfillment is crucial for maintaining positive customer relationships, building a strong brand, gaining a competitive advantage, optimizing operations, and fostering customer loyalty.

5 Order fulfillment options

Various order fulfillment options exist to meet different business needs and customer demands. Here are five common order fulfillment methods:

In-House Fulfillment

This method involves a business managing the entire fulfillment process internally, from receiving orders to picking, packing, and shipping. It provides direct control over the process but requires dedicated warehouse space, staff, and resources.

Outsourced Fulfillment (3PL – Third-Party Logistics)

Companies can outsource their order fulfillment to third-party logistics providers. 3PL companies handle various aspects of the fulfillment process, including warehousing, inventory management, picking, packing, and shipping. This option reduces the burden on the business, allowing them to focus on other core activities.

Dropshipping

In dropshipping, the retailer doesn’t keep the products in stock. Instead, when a customer places an order, the retailer purchases the item from a third party (usually a manufacturer or wholesaler) and has it shipped directly to the customer. The retailer doesn’t handle the product directly, which reduces inventory costs but might limit control over shipping times and product availability.

Crowdsourced Fulfillment

This method involves utilizing a network of individuals, often independent contractors or freelance couriers, to fulfill orders. Companies can leverage this network for last-mile delivery or quick turnaround in specific geographic locations. Examples include apps that use local drivers for quick deliveries.

Hybrid Fulfillment

This approach combines different fulfillment methods to leverage their individual advantages. For example, a company might use in-house fulfillment for certain products while using a 3PL for others. This hybrid model offers flexibility and customization based on product type, demand, or other factors.

Each fulfillment option comes with its own set of advantages and limitations, and the choice often depends on factors such as the nature of the products, customer expectations, business scalability, cost considerations, and the level of control the company wants to maintain over the process. Businesses frequently tailor their approach to a combination of these options to best meet their specific needs and market demands.