At LeuLeu LLC, we recognize the power of the ending inventory formula in optimizing inventory management. Successful business operations hinge on maintaining the perfect balance of stock – having the right products ready when they are needed. This article will delve into the critical role the ending inventory formula plays in steering your operations towards success. Additionally, we’ll equip you with practical strategies and insights to refine your inventory management practices, ultimately boosting your online visibility and ranking higher on Google search results.

Understanding Ending Inventory

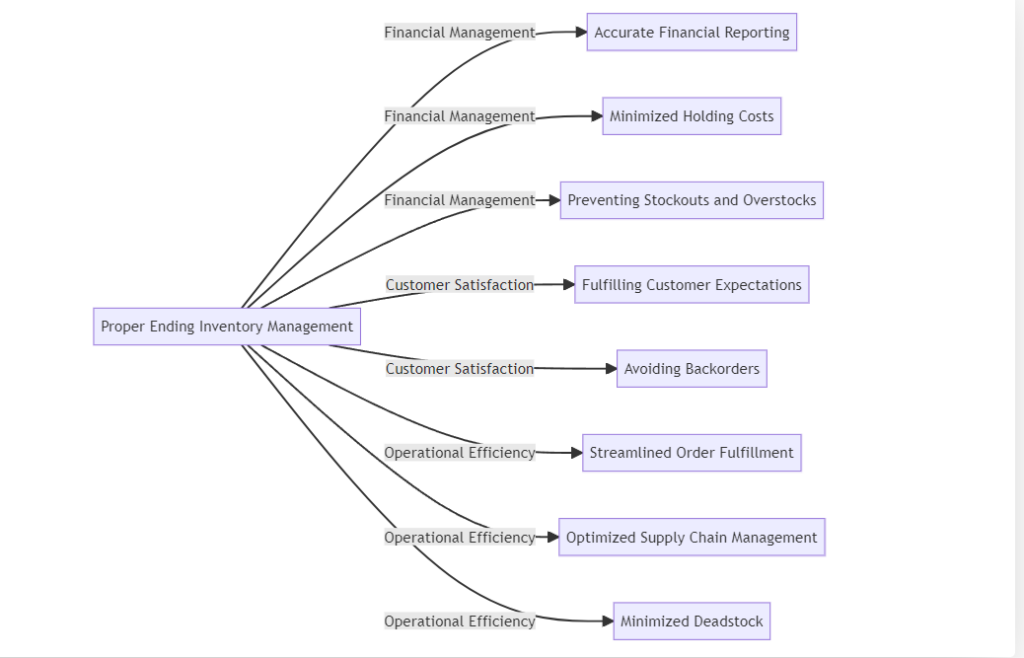

Ending inventory refers to the value of products that remain unsold at the end of the accounting period. It includes goods that are still in stock, waiting to be sold or used. Effectively managing ending inventory is important for many reasons, including financial management, customer satisfaction, and operational efficiency.

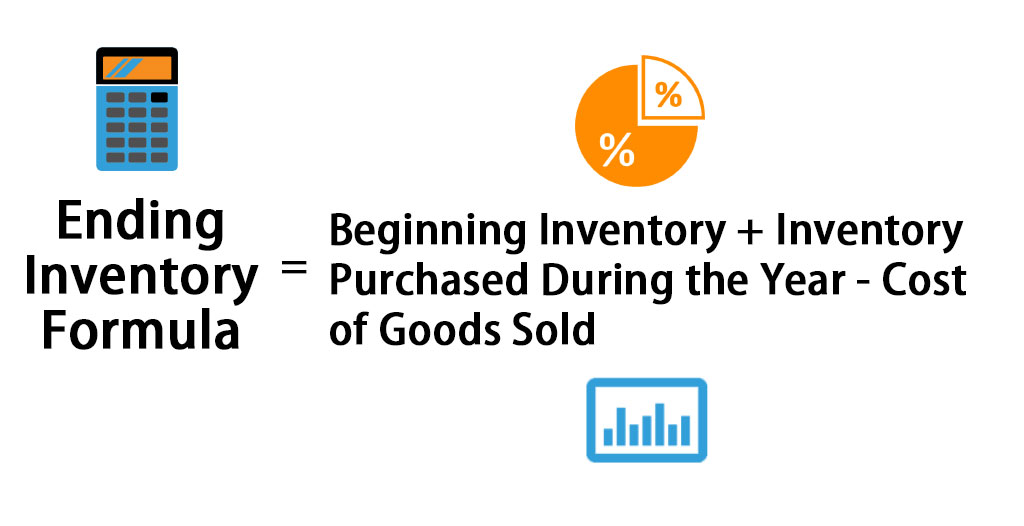

Calculating Ending Inventory: The Formula

The formula to calculate ending inventory is simple and straightforward:

This calculation provides the physical count of products available in your warehouse by the end of the period. While it’s a seemingly simple equation, each component plays a significant role in shaping your business operations and overall profitability.

Financial Management Benefits

- Accurate Financial Reporting: Proper management of ending inventory ensures that your financial reports accurately reflect the value of your inventory. This information is essential for calculating key financial ratios, such as the cost of goods sold (COGS) and gross profit margin. Accurate financial reporting helps you make informed business decisions and present reliable financial information to stakeholders.

- Minimized Holding Costs: Efficiently managing your ending inventory helps reduce holding costs associated with storage, insurance, and obsolescence. By avoiding excess inventory, you can free up valuable capital for other business activities and improve your cash flow.

- Preventing Stockouts and Overstocks: Balancing your inventory levels optimally helps minimize stockouts and overstocks. Stockouts lead to lost sales and dissatisfied customers, while overstocks tie up valuable resources and increase the risk of product obsolescence. Maintaining the right inventory levels ensures that you can meet customer demand while minimizing unnecessary costs.

Customer Satisfaction and Retention

- Fulfilling Customer Expectations: Efficient ending inventory management enables you to fulfill customer orders promptly. By having the right products in stock, you can provide faster order processing and reduce lead times. This, in turn, improves customer satisfaction, enhances your reputation, and fosters customer loyalty.

- Avoiding Backorders: Backorders occur when customer demand exceeds the available inventory. By effectively managing your ending inventory, you can minimize backorders and ensure that customers receive their orders in a timely manner. Avoiding backorders helps prevent potential customer dissatisfaction and encourages repeat purchases.

Operational Efficiency

- Streamlined Order Fulfillment: Proper inventory management allows for streamlined order fulfillment processes. By organizing your inventory effectively and implementing efficient picking and packing procedures, you can reduce order processing time and improve operational efficiency.

- Optimized Supply Chain Management: Managing ending inventory helps you gain better control over your supply chain. By accurately forecasting demand, coordinating with suppliers, and maintaining optimal inventory levels, you can reduce lead times and improve overall supply chain efficiency.

- Minimized Deadstock: Deadstock refers to products that are no longer in demand or have become obsolete. Effectively managing ending inventory helps minimize deadstock, ensuring that you are not burdened with unnecessary inventory that cannot be sold. This reduces the risk of financial losses associated with deadstock and frees up warehouse space for more profitable products.

Strategies for Efficient Ending Inventory Management

- Implementing Inventory Tracking Systems: Utilizing inventory tracking systems, such as inventory management software or barcode scanning systems, can help you accurately monitor and control your ending inventory. These systems provide real-time data on inventory levels, facilitate automated reordering, and enable efficient demand forecasting.

- Conducting Regular Inventory Audits: Regularly auditing your inventory helps identify discrepancies and potential issues. By performing physical counts and reconciling them with your records, you can ensure the accuracy of your inventory data and minimize errors.

- Analyzing Sales Trends: Analyzing sales trends and historical data helps you make informed decisions regarding inventory levels. By identifying seasonal fluctuations, demand patterns, and product life cycles, you can adjust your inventory accordingly and avoid excess stock or stockouts.

- Collaborating with Suppliers: Building strong relationships with your suppliers is essential for efficient inventory management. By communicating and collaborating effectively, you can optimize order quantities, delivery schedules, and pricing terms, ensuring a steady supply of products without unnecessary inventory accumulation.

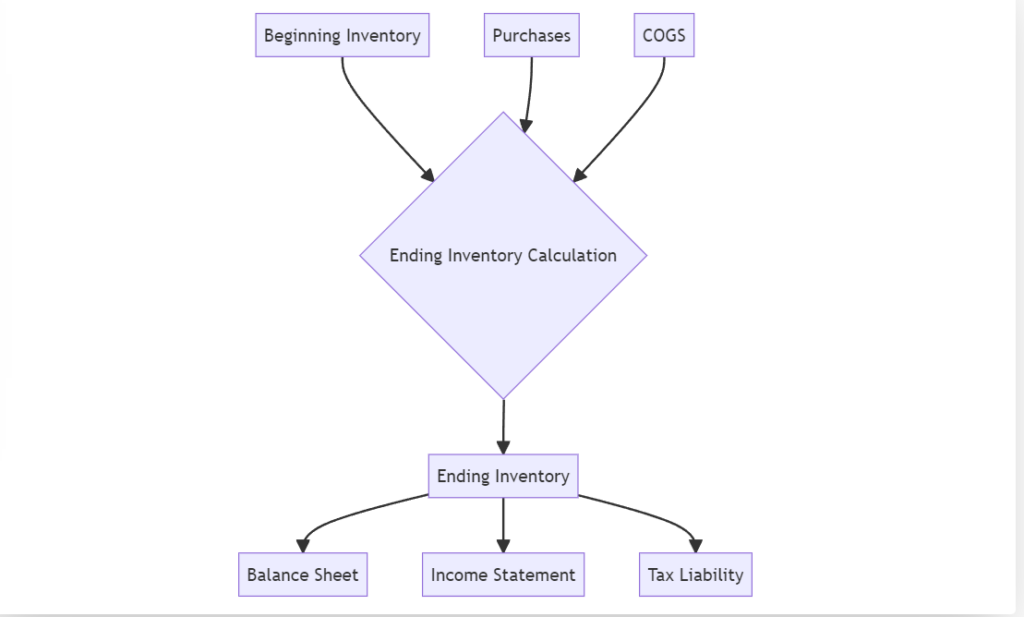

Visual Representation of Efficient Ending Inventory Management

Implementing Best Practices for Ending Inventory Management

To further enhance your ending inventory management practices, consider implementing the following best practices:

1. Embrace Just-in-Time (JIT) Inventory

The just-in-time inventory approach focuses on receiving goods from suppliers as close to the time of sale as possible. By reducing the amount of inventory stored in your warehouse, you can minimize holding costs and free up capital for other business needs. However, it’s essential to maintain strong relationships with reliable suppliers to ensure timely deliveries.

2. Utilize Demand Forecasting

Accurate demand forecasting is a valuable tool for effective ending inventory management. By analyzing historical sales data, market trends, and customer preferences, you can anticipate future demand patterns and adjust your inventory levels accordingly. This proactive approach helps prevent stockouts and minimizes excess inventory.

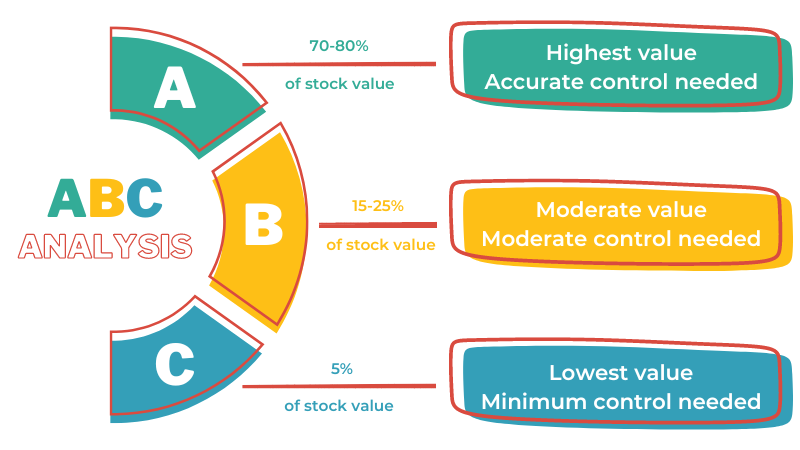

3. Implement ABC Analysis

ABC analysis categorizes inventory items based on their value and demand. Classifying items into three categories—A, B, and C—allows you to prioritize your inventory management efforts. Focus on optimizing the management of high-value items (A) while adopting more flexible inventory strategies for low-value items (C).

4. Optimize Warehouse Layout and Organization

An efficiently organized warehouse promotes smooth inventory management processes. Consider implementing logical product placement, clear labeling systems, and efficient picking and packing procedures. This optimization reduces the time required to locate and retrieve items, enhancing operational efficiency.

5. Embrace Technology Solutions

Leverage technology to streamline your ending inventory management. Inventory management software offers features such as real-time tracking, automated reordering, and integration with other business systems like sales and accounting. Additionally, barcode scanning systems and radio-frequency identification (RFID) technology can improve accuracy and speed in inventory tracking.

6. Regularly Review and Update Inventory Policies

As your business evolves, it’s crucial to review and update your inventory policies periodically. Regularly assess your reorder points, safety stock levels, and lead times to ensure they align with changing market conditions and customer demands. Flexibility and adaptability are key in maintaining optimal inventory management practices.

Impact of Ending Inventory on Financial Statements

The value of the ending inventory directly impacts a company’s balance sheet and income statement. On the balance sheet, it is reported as a current asset. On the income statement, it affects the calculation of the COGS, which subsequently influences the gross profit margin.

Mitigating the Risks of Mismanaged Ending Inventory

In the world of inventory management, balancing the scales is a delicate art. Having too much inventory on hand can result in higher holding costs, wasted space, and potential losses from expired or outdated items. On the flip side, too little inventory can lead to missed sales opportunities, delays in production, and disappointed customers.

This is where the ending inventory formula plays a crucial role. It allows businesses to manage their inventory in a more systematic and informed manner, reducing the risks of inventory mismanagement.

The Influence of the Ending Inventory Formula on Your Company’s Tax Obligations

The value of your ending inventory also impacts your tax liability. If your inventory value increases, your taxable income can decrease, as the increase in inventory is considered an investment in future sales. Therefore, it’s crucial to accurately calculate and report ending inventory values.

Outrank the Competition with Effective Ending Inventory Management

By implementing these best practices for ending inventory management, you can position your business to outrank competitors and achieve higher visibility on search engine results pages. Remember, the goal is to provide valuable, well-optimized content that offers actionable insights to readers searching for information on ending inventory management.

At LeuLeu LLC, we are dedicated to helping businesses succeed through effective inventory management strategies. By optimizing your ending inventory practices, you can enhance financial performance, increase customer satisfaction, and streamline operations. Stay ahead of the competition by prioritizing efficient ending inventory management and continuously refining your processes to adapt to changing market dynamics.

Remember, effective ending inventory management is a journey rather than a destination. Continuously monitor and evaluate your inventory management practices, keeping an eye on emerging trends and technological advancements. By staying proactive and adaptive, you can position your business for long-term success in today’s competitive landscape.

If you have any questions or would like to explore how LeuLeu LLC can assist you further, please don’t hesitate to reach out. Our team of experts is here to help you optimize your inventory management practices and achieve your business goals.

Together, let’s unlock the full potential of your ending inventory management and drive your business to new heights of success!