The modern supply chain is a complex and interconnected web of businesses, suppliers, and logistics operations. Efficient supply chain management is crucial for meeting customer demand while optimizing costs. However, one often underestimated challenge that can send ripples of disruption throughout the entire supply chain is the “bullwhip effect.” This phenomenon describes the amplification of demand variability as it moves upstream in the supply chain, causing a cascade of consequences that impact businesses at every level of the chain. In this discussion, we will delve into how the bullwhip effect impacts the supply chain, examining the causes, consequences, and strategies to mitigate its detrimental effects.

What is the bullwhip effect?

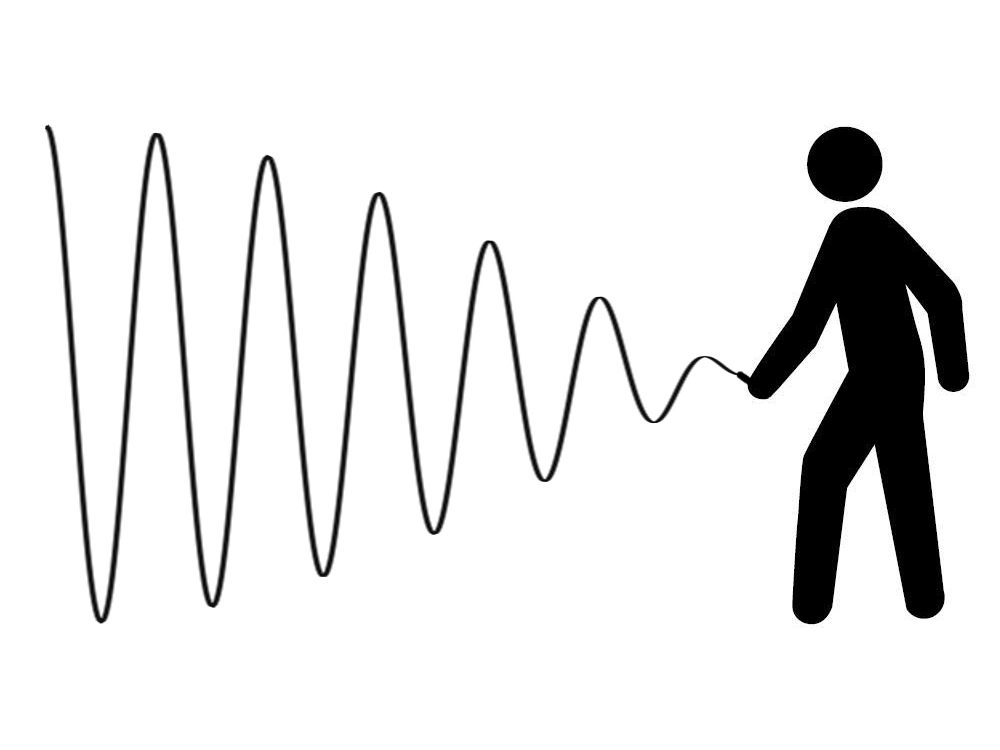

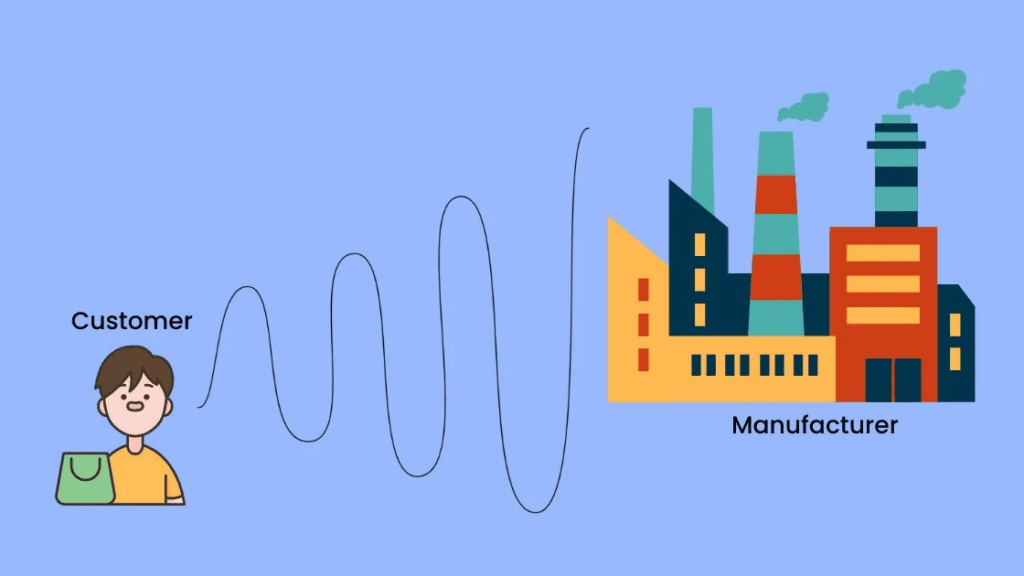

The bullwhip effect, also known as the “whiplash effect,” is a phenomenon in supply chain management where small fluctuations in customer demand for a product can lead to increasingly larger fluctuations in demand as one moves up the supply chain. It is called the “bullwhip” effect because the graph of this amplification effect looks like the shape of a bullwhip’s handle. ith the handle representing the small and stable customer demand, and the whip’s lash representing the increasingly volatile and amplified orders as you move upstream through the supply chain.

Several factors contribute to the bullwhip effect:

Demand Forecasting

Companies often rely on demand forecasts to plan their production and inventory levels. However, forecasting is subject to errors. nd even small inaccuracies can be magnified as they move upstream in the supply chain.

Order Batching

To save on ordering and transportation costs, businesses sometimes place orders in batches rather than continuously. These batch orders can lead to fluctuations in demand as suppliers try to interpret the sporadic orders.

Lead Times

Variability in lead times, which is the time it takes for an order to be processed and delivered. Itcan also contribute to the bullwhip effect. Long lead times can exacerbate the impact of fluctuations in demand.

Lack of Communication

Poor communication and information sharing between supply chain partners can result in misunderstandings and exaggerate the bullwhip effect. Each party may make independent decisions without a full understanding of the entire supply chain’s dynamics.

The bullwhip effect can have several negative consequences, including increased costs, inefficient use of resources, and poor customer service. To mitigate the bullwhip effect, companies can take measures to improve communication and collaboration throughout the supply chain, use more accurate demand forecasting methods, adopt inventory management techniques like just-in-time (JIT), and reduce order batching. These strategies help smooth out demand fluctuations and create a more efficient and responsive supply chain.

How the bullwhip effect impacts the supply chain

The bullwhip effect is a phenomenon in supply chain management that describes the amplification of demand variability as it moves upstream in the supply chain. This effect can have significant negative impacts on the supply chain, including:

Increased Inventory Costs

As demand fluctuations are magnified as they move upstream, companies in the supply chain often overreact to these fluctuations by carrying excess inventory. This excess inventory ties up capital and increases carrying costs, which can be a significant financial burden for businesses.

Poor Forecasting Accuracy

It can result in inaccurate demand forecasts. Inaccurate forecasts can lead to production and procurement decisions that are not aligned with actual customer demand. It can result in stockouts or overstock situations. eading to lost sales or increased carrying costs.

Inefficiencies in Production and Distribution

When the demand signal is distorted by the bullwhip effect, production schedules and distribution plans become erratic. This can lead to inefficiencies in production, higher production and transportation costs, and difficulty in managing capacity effectively.

Strained Supplier Relationships

Suppliers often bear the brunt of the bullwhip effect as they deal with order fluctuations and changing requirements. This can strain relationships with suppliers, lead to increased lead times, and result in less favorable terms for the buying company.

Reduced Customer Service and Satisfaction

It can lead to stockouts or overstocks, which negatively impact customer service and satisfaction. Customers may experience delayed deliveries, unavailability of products, or receiving products they didn’t order, all of which can harm a company’s reputation and customer loyalty.

To mitigate the bullwhip effect, companies can employ various strategies such as improving communication and collaboration within the supply chain, using more accurate demand forecasting methods, implementing just-in-time (JIT) inventory practices, and adopting technologies like demand planning software and automated order management systems. By addressing the bullwhip effect, companies can reduce costs, improve customer service, and enhance the overall efficiency of their supply chains.