Inventory replenishment is a critical aspect of supply chain management that fuels the efficiency and profitability of businesses across various industries. It entails the delicate balance of ensuring that products and materials are readily available to meet customer demand while avoiding the financial pitfalls of overstocking. The post delves into this fundamental business process, unraveling the intricacies of managing stock levels to optimize operational performance. In the following discussion, we will explore the key principles, strategies, and tactics that underlie inventory replenishment.

What is inventory replenishment?

is the process of restocking and maintaining a consistent level of inventory or stock in a business, store, or supply chain. This practice ensures that an organization has an adequate supply of products or materials on hand to meet customer demand, fulfill orders, and support its operations without experiencing stockouts or overstocking.

What is replenishment method of inventory management?

Replenishment methods in inventory management refer to the strategies and approaches used to maintain and restock inventory levels to meet demand while minimizing costs and optimizing the supply chain. These methods are crucial for businesses to ensure they have the right amount of inventory on hand to satisfy customer demand without overstocking or running out of stock.

Why is inventory replenishment important for ecommerce retailers?

It is essential for e-commerce retailers for several compelling reasons:

Customer Satisfaction

E-commerce customers expect timely and reliable delivery of their orders. Inventory replenishment ensures that products are readily available, leading to faster order fulfillment and higher customer satisfaction.

Preventing Stockouts

Running out of stock can lead to lost sales, customer frustration, and potentially damage to a retailer’s reputation. An effective inventory replenishment strategy helps e-commerce retailers avoid stockouts and ensures that products are consistently available for purchase.

Reducing Holding Costs

Maintaining excess inventory ties up capital and storage space. Effective inventory replenishment helps minimize these costs by aligning stock levels with actual demand, reducing warehousing, depreciation, and insurance expenses.

Optimizing Supply Chain Efficiency

It enables e-commerce retailers to manage their supply chain more efficiently. It allows businesses to forecast demand, reduce lead times, and minimize the risk of over-ordering or under-ordering products.

Data-Driven Decision-Making

Replenishment strategies often involve data analysis, trend tracking, and the use of inventory management tools. These data-driven insights empower e-commerce retailers to make informed decisions about what products to stock and in what quantities, improving overall business performance and agility.

Adapting to E-commerce Trends

E-commerce trends and customer preferences can change rapidly. Inventory replenishment strategies help retailers adapt to evolving market conditions and consumer behavior, ensuring they stock the right products and meet changing demand effectively.

In summary, it plays a pivotal role in ensuring that e-commerce retailers can meet customer expectations, reduce costs, and maintain an efficient and responsive supply chain. It is essential for delivering a positive customer experience, driving sales, and achieving long-term success in the e-commerce industry.

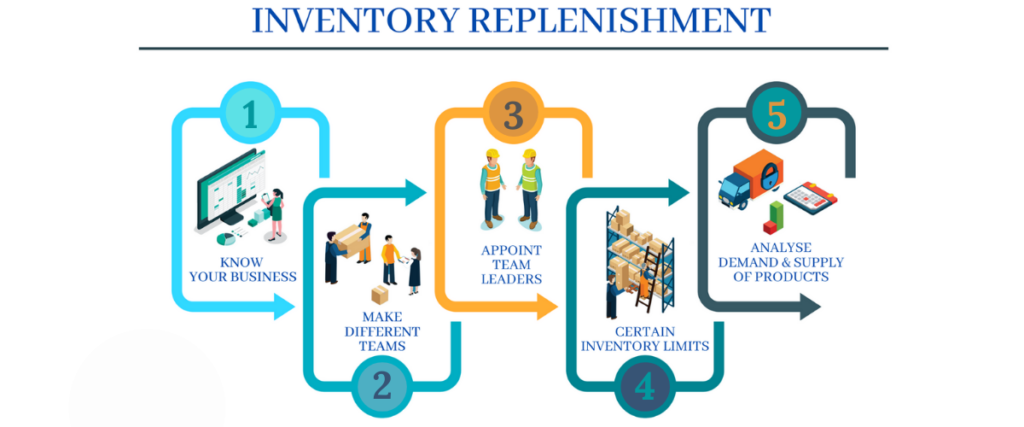

How do you increase inventory replenishment?

Increasing inventory replenishment involves improving the efficiency and accuracy of your inventory management processes. Here are three key ways to achieve this:

Demand Forecasting and Planning:

- Implement robust demand forecasting methods that take historical sales data, market trends, seasonality, and other relevant factors into account. Accurate forecasts help you predict future demand more effectively.

- Use demand planning software and tools to automate the process and analyze data efficiently. This allows you to make informed decisions about order quantities and timing.

Supply Chain Optimization:

- Streamline your supply chain operations to reduce lead times and improve order fulfillment efficiency. Work closely with suppliers to negotiate favorable terms, reduce transit times, and minimize the risk of delays.

- Implement a just-in-time (JIT) inventory approach when feasible. JIT helps you maintain lower inventory levels while ensuring timely replenishment.

Inventory Management Technology:

- Invest in advanced inventory management software and systems that offer real-time visibility into stock levels and automate order placement when inventory falls below predetermined thresholds.

- Use barcoding and RFID technology to track inventory accurately and reduce errors. These technologies make the inventory replenishment process more efficient and less prone to mistakes.

By focusing on demand forecasting, optimizing your supply chain, and adopting inventory management technology, you can increase the accuracy and efficiency of your processes, ultimately reducing stockouts, minimizing overstocking, and improving your overall inventory management strategy.