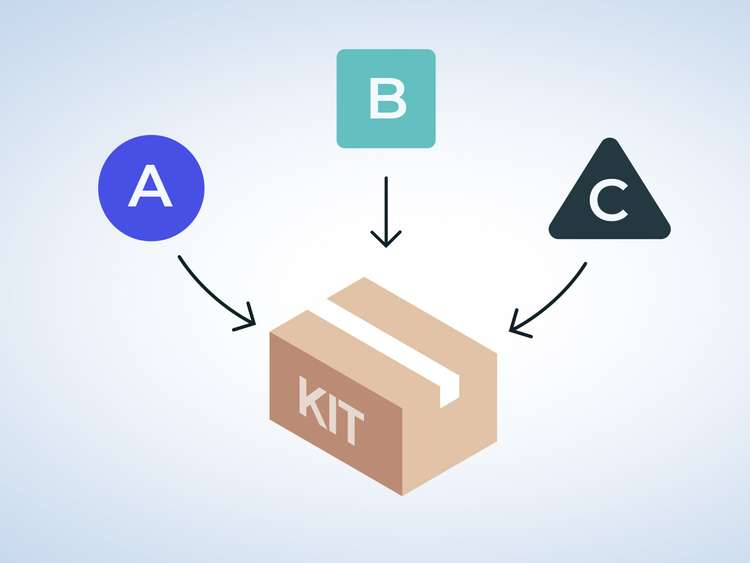

Kitting, often described as the process of grouping and packaging individual components or parts into a single, cohesive unit, plays a pivotal role in optimizing efficiency and streamlining operations across various industries. This practice not only simplifies assembly and task completion but also offers a multitude of benefits that can significantly impact productivity and cost-effectiveness.

In this discussion, we will explore the fundamental concept of kitting, shedding light on what it entails, and delve into the numerous advantages it brings to businesses and processes.

What is kitting?

Kitting is a process used in manufacturing and logistics, where individual components or parts are gathered together and packaged as a single kit or set. These kits typically contain all the items needed to complete a specific task, assembly, or process. Kitting is a strategy to streamline operations and improve efficiency in various industries, including manufacturing, electronics, aerospace, and automotive.

The Kitting Process

The kitting process typically involves several steps to assemble kits efficiently. Here are five key steps in the kitting process:

Planning and Requirements Gathering:

- Define the purpose of the kit: Determine the specific task, assembly, or purpose for which the kit is being prepared.

- Identify components: List all the components, parts, tools, and materials required for the kit.

- Determine quantities: Specify the quantities of each component needed for the task.

- Consider customization: If kits need to be customized for different purposes or customers, plan for this flexibility.

Component Acquisition:

- Procure or gather all the required components and materials based on the list generated during the planning phase.

- Ensure that all components are in good condition and meet quality standards.

Kit Assembly:

- Assemble the kit by carefully placing each component into a designated container or packaging. This can be a box, bag, or any other appropriate packaging.

- Follow a standardized procedure to ensure consistency in the assembly process.

- Label or mark the kit with essential information, such as a kit number, contents, and usage instructions.

Quality Control and Inspection:

- Before finalizing the kit, conduct a quality control check to ensure that all components are present, in the correct quantities, and in good condition.

- Verify that the kit meets any required quality or safety standards.

- Document the inspection results for quality assurance purposes.

Storage and Distribution:

- Store the assembled kits in a designated storage area, ensuring they are easily accessible and well-organized.

- Create an inventory record for each kit to track stock levels and monitor usage.

- When a task or order requires a kit, retrieve it from storage, and distribute it to the relevant user or workstation.

- Monitor kit usage and restock components as needed to maintain an adequate supply of kits.

The kitting process can vary in complexity and detail depending on the industry and specific requirements. It is crucial to maintain accurate records, conduct regular quality control checks, and adjust the process as needed to meet changing demands or customization requirements. Kit assembly is a key component of improving efficiency and productivity in various applications, from manufacturing to service industries.

Types of Kitting

Kitting can take on various forms and can be adapted to different industries and specific needs. Here are some common types of kitting:

Assembly Kitting

This type of kitting involves gathering all the necessary components and parts required to assemble a product. It is often used in manufacturing industries where products are built from various components. By pre-packaging these components together as kits, assembly workers can complete their tasks more efficiently, with fewer errors, and in less time.

Medical Kitting

Medical kitting is prevalent in healthcare and medical settings. It involves the preparation of kits that contain all the essential medical supplies, instruments, and medications needed for specific medical procedures or tasks. These kits ensure that healthcare providers have everything readily available to deliver the required care efficiently and with a focus on patient safety.

Retail Kitting

Retailers use retail kitting to create product bundles or kits for sale to customers. These kits typically consist of related or complementary items packaged together. For example, a computer store might offer a gaming kit that includes a gaming laptop, keyboard, mouse, and headset. Retail kitting can encourage upselling, simplify customers’ shopping experience, and promote specific products or product combinations.

These are just a few examples of kitting types, and the concept can be adapted to various industries and applications to enhance efficiency, organization, and customer satisfaction.

What Are the Benefits of Kitting?

Kitting offers several benefits across various industries and processes. Here are soem advantages of implementing kitting:

Enhanced Efficiency

Kitting streamlines operations by providing workers with all the necessary components and parts in a single package. This reduces the time spent searching for and gathering individual items, leading to increased productivity and shorter assembly or task completion times.

Reduced Errors

With all the required components in one kit, the likelihood of missing parts or assembly mistakes is minimized. This improves product quality and reduces the need for rework or corrections, ultimately leading to higher customer satisfaction.

Inventory Management

Kitting helps manage inventory more effectively by grouping components together in kits with known quantities. This reduces the risk of overstocking or stockouts, simplifies inventory control, and streamlines the reordering process, which can lead to cost savings.

Customization

Kitting allows for flexibility in product or service offerings. Kits can be customized to meet specific customer requirements or to address different project needs. This flexibility can improve customer satisfaction and support a wider range of applications.

Cost Savings

Kitting can lead to cost savings in various ways, including reduced labor costs, minimized waste, and optimized inventory management. By providing components in pre-assembled kits, it also reduces the costs associated with assembly errors, such as incorrect part usage.

These benefits make kitting a valuable tool in industries such as manufacturing, healthcare, retail, and many others, where efficiency, quality control, and inventory management are essential for success.

Kit on Demand vs Pre-Kitting

“Kit on Demand” and “Pre-Kitting” are two different approaches to managing and using kits in various industries and applications. Here’s an explanation of each:

Kit on Demand:

- On-Demand Preparation: In a “Kit on Demand” approach, kits are prepare and assemble only when they are need, typically in response to a specific request or order.

- Flexibility: This approach provides a high degree of flexibility since kits can be customize and adapted to specific customer orders or changing requirements.

- Reduced Inventory: Kit on Demand helps in reducing the need for extensive inventory storage because kits are not preassemble and stored in anticipation of demand.

- Efficiency: It can be efficient in situations where demand is unpredictable or varies widely, as it minimizes the risk of overstocking or obsolescence.

- Customization: Kits can be easily tailor to meet individual customer requirements, ensuring that customers receive exactly what they need.

Pre-Kitting:

- Pre-Assembled Kits: In the “Pre-Kitting” approach, kits are assemble and packaged in advance, based on an anticipated demand or specific standards.

- Consistency: This approach provides a consistent and standardize way of handling tasks, assembly, or service, as the kits are prepared ahead of time with predetermined contents.

- Efficiency: Pre-kitting can lead to increased efficiency when demand is relatively stable and predictable. It minimizes the time spent on assembling kits for each order.

- Inventory Management: It may require more storage space and careful inventory management because pre-assembled kits need to be store until they are use or sold.

- Streamlined Processes: Pre-kitting simplifies operations by ensuring that all required components are readily available without the need for on-the-fly customization.

The choice between “Kit on Demand” and “Pre-Kitting” depends on the specific needs of a business or process. If demand is highly variable, customization is essential, or inventory management is a concern, “Kit on Demand” may be the preferred approach. In contrast, when processes are standardize, demand is relatively stable, and efficiency in operations is a priority, “Pre-Kitting” may be more appropriate. Some businesses may even use a combination of both approaches to balance flexibility and efficiency.